Difference between revisions of "Dragon Calibration"

| Line 567: | Line 567: | ||

*Next, press the next button to register the information with the software and continue. | *Next, press the next button to register the information with the software and continue. | ||

| − | |||

| − | |||

| Line 608: | Line 606: | ||

*This page automatically use the information from the two previous steps and attempt to find the center of the tubing. | *This page automatically use the information from the two previous steps and attempt to find the center of the tubing. | ||

| − | *If the location of the laser is not completely centered on the tube, repeat the previous steps to ensure an accurate calibration, then | + | *If the location of the laser is not completely centered on the tube, repeat the previous steps to ensure an accurate calibration, then mark the absolute center with a marker. |

| − | |||

| + | *Then, click the next button to continue. | ||

Revision as of 10:59, 19 May 2016

"This guide will help you understand all of the processes and procedures involved in assembling your Dragon Machine and calibrating your Dragon Software to your machine."

"Please take your time in assembling and calibrating your new Dragon Machine/Software by following all of these steps thoroughly. This should take anywhere from 2-3 hours based on how you pay attention to detail, how much help you have and if you are technologically adept or not."

"Each step will have a short video attached to it showing how that particular step is meant to be completed by the operator."

Contents

- 1 Introduction

- 2 Select Computer Setup

- 3 Chuck Travel (X Axis)

- 4 Chuck Rotation (Y Axis)

- 5 Toolset Height Control (Z Axis)

- 6 A-Axis Movement: Tool Change

- 7 Check Homing Switch (X Axis)

- 8 Check Homing Switch (A Axis)

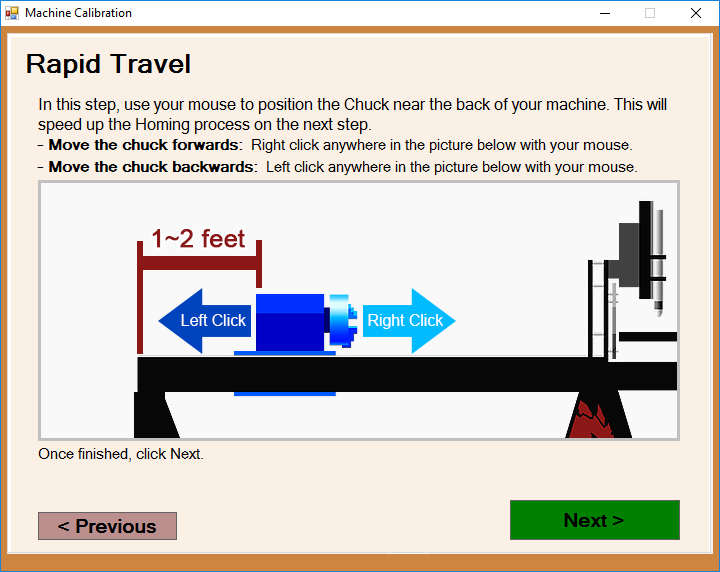

- 9 Rapid Travel

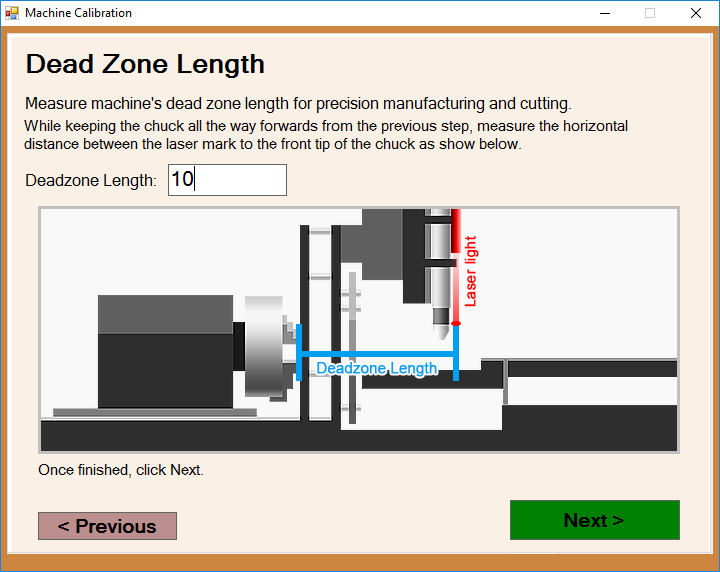

- 10 Dead Zone Length

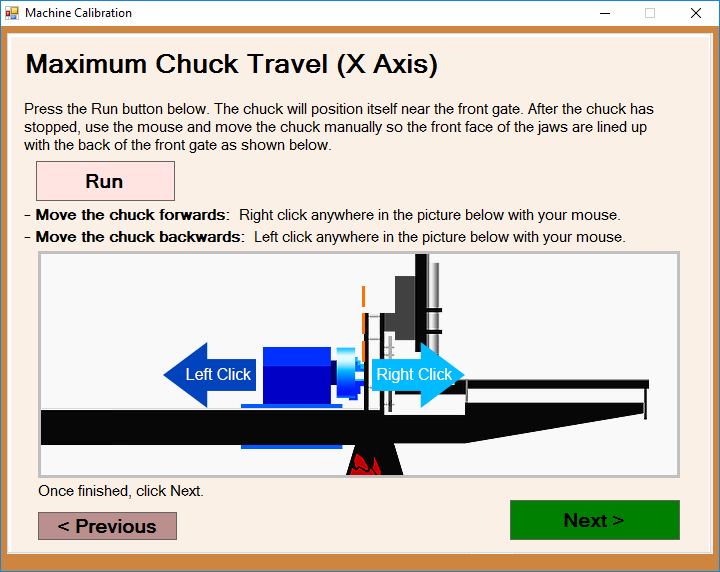

- 11 Maximum Chuck Travel (X Axis)

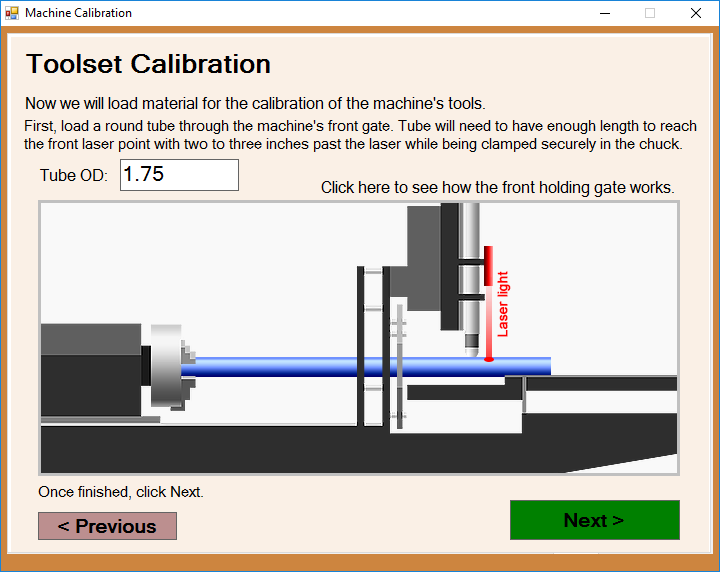

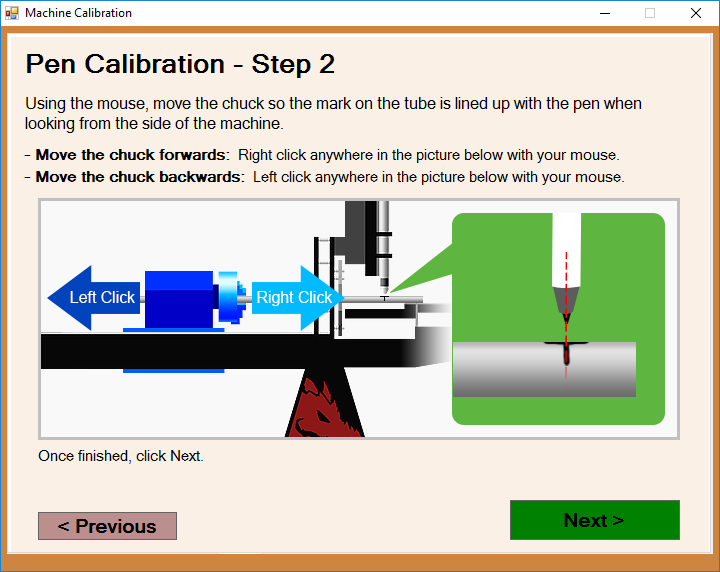

- 12 Toolset Calibration)

- 13 Laser Calibration - Step 1

- 14 Laser Calibration - Step 2

- 15 Laser Calibration - Step 3

- 16 Engraver Alignment (X-Axis)

- 17 Engraver Height Adjustment

- 18 Engraver Calibration: Verify

- 19 Torch Centering

- 20 Torch Alignment (X-Axis)

- 21 Torch Height Adjustment

- 22 Torch Calibration: Verify

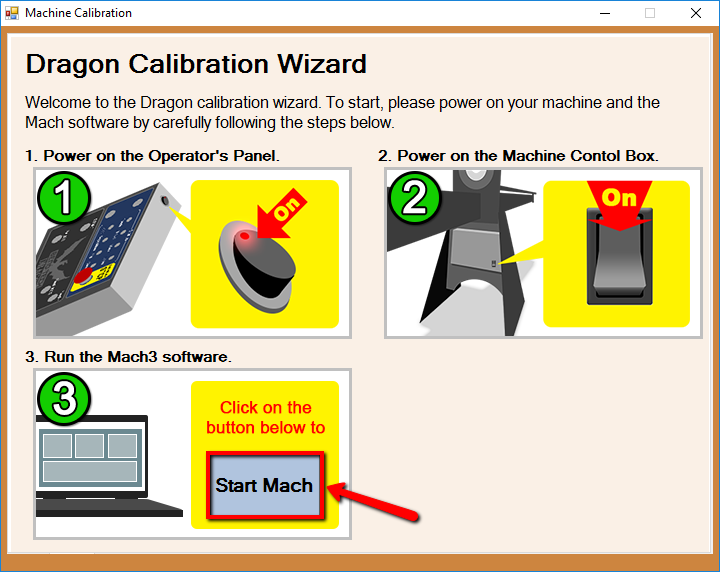

Introduction

- This introduction gives you a small insight into the tasks that are expected during this calibration and instructs you to turn on the power on the control panel and on the Dragon machine.

- When the machine is turned on, click the "Start Mach" button to continue to the next page.

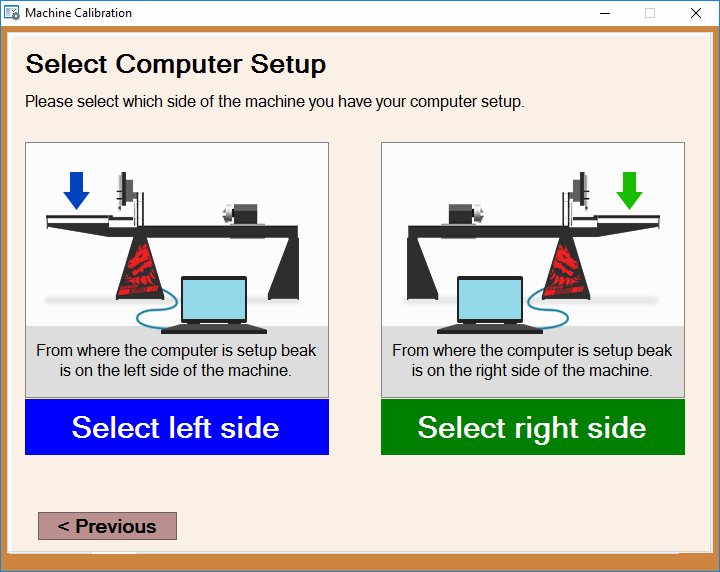

Select Computer Setup

- The "Select Computer Setup" page will open your Mach program and it will ask you which side of the Dragon machine your computer is located on.

- Select the image that describes your computer's location in reference to the Dragon machine to move on to the next page in the calibration.

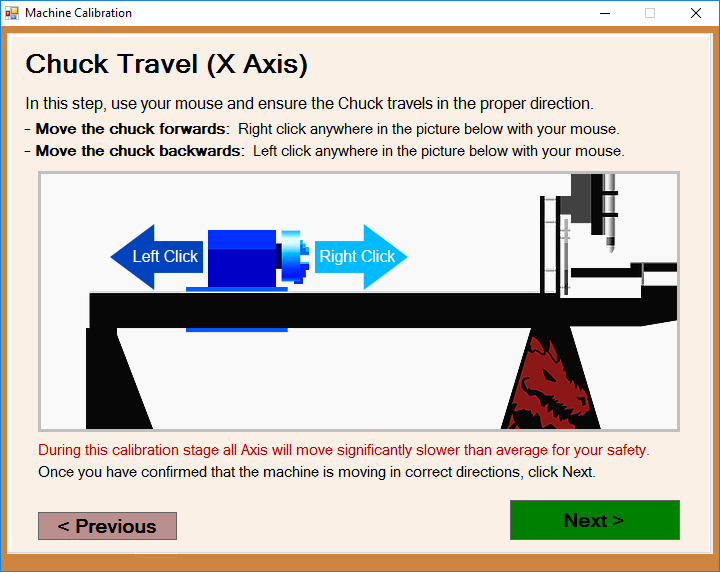

Chuck Travel (X Axis)

- This page will prompt you to adjust the chuck travel to ensure that it is moving in the proper direction when you press the left and right buttons on your mouse.

- Watch the video HERE

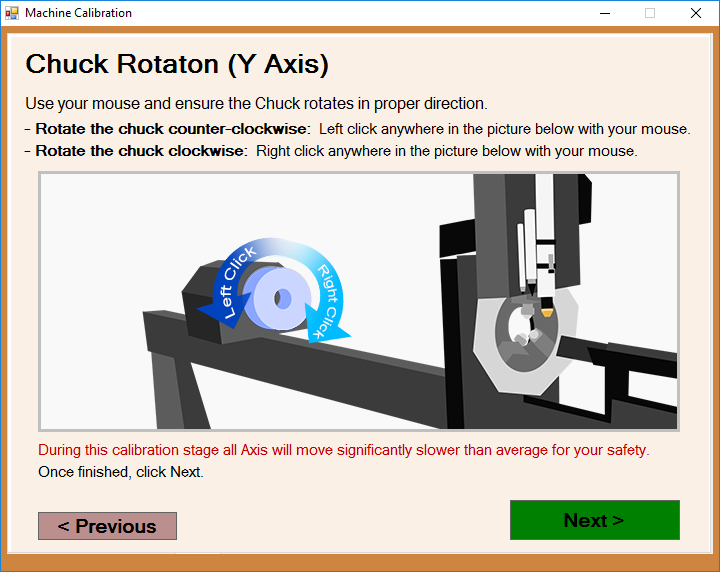

Chuck Rotation (Y Axis)

- This page will prompt you to adjust the chuck rotation to ensure that it is rotating in the proper direction when you press the left and right buttons on your mouse.

- Watch the video HERE

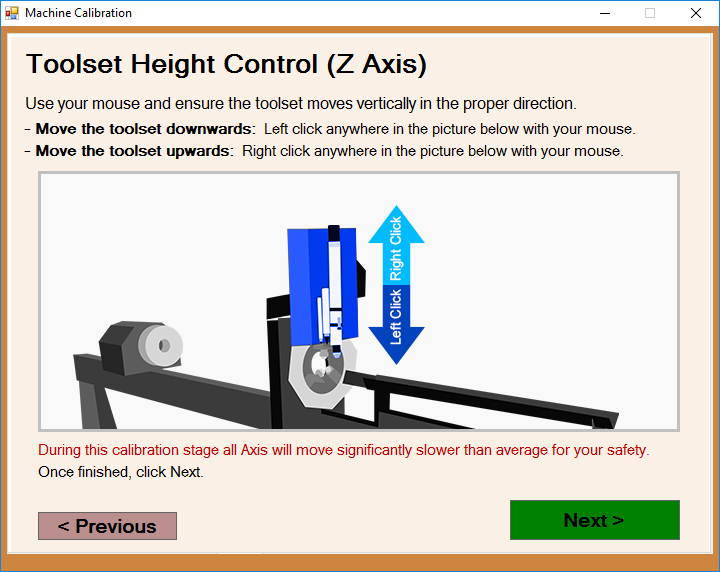

Toolset Height Control (Z Axis)

- This page will prompt you to adjust the tool height to ensure that the toolset is moving in the proper direction when you press the left and right buttons on your mouse.

- Watch the video HERE

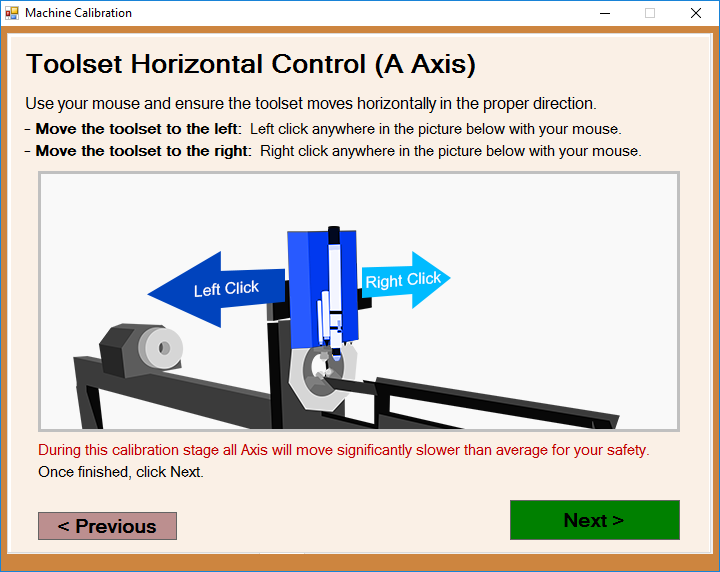

A-Axis Movement: Tool Change

- This page will prompt you to adjust the toolset's horizontal movement to ensure that it is moving in the proper direction when you press the left and right buttons on your mouse.

- Watch the video HERE

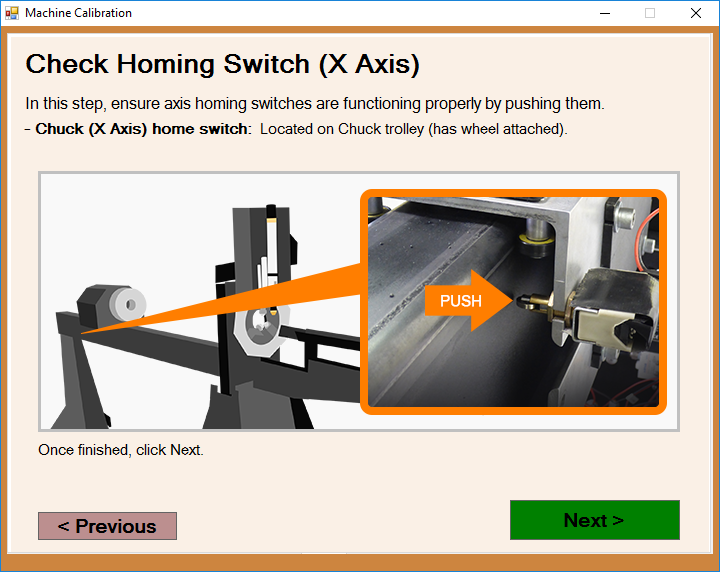

Check Homing Switch (X Axis)

- The page will point to the manual switch for the X axis. You are prompted to press the X axis switch followed the Next button.

- Watch the video HERE

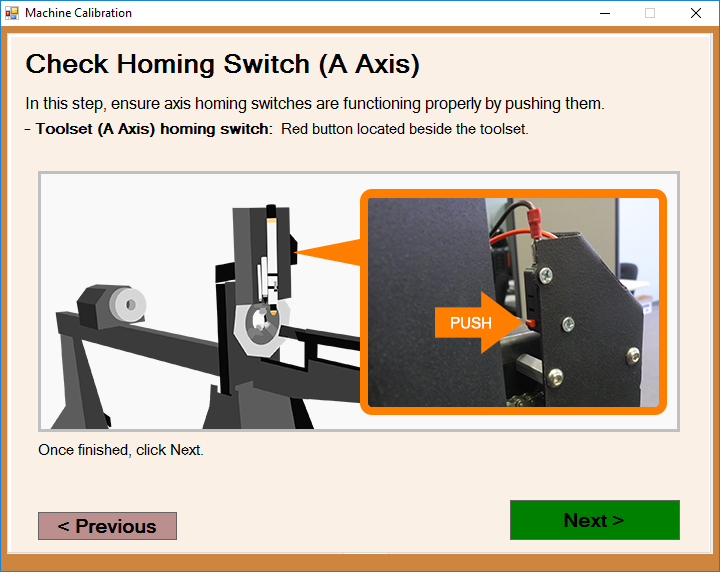

Check Homing Switch (A Axis)

- The page will point to the manual switch for the A axis. You are prompted to press the A axis switch followed the Next button.

- Watch the video HERE

Rapid Travel

- This page will prompt you to move the chuck near the back of the machine using the left and right buttons on your mouse followed the Next button.

- Watch the video HERE

Dead Zone Length

- This page will prompt you to measure the length from the front jaws of the chuck to the laser light when the chuck is in its front most position.

- Enter the measured length in the Deadzone Length value field and select the next button when you're finished.

Maximum Chuck Travel (X Axis)

- This page will prompt you to click on the Run button on the screen in order to position the chuck near the front gate. Then, back the chuck off so that the jaws of the chuck are lined up with the rear face of the front gate.

- Then, click the next button.

Toolset Calibration)

- This page will prompt you to load the material used for this calibration, making sure to locate the end of the tubing a few inches past the laser positioning light.

- Enter the OD of the tubing into the Tube OD value field and click the next button to continue.

Front Holding Gate Operation

- Click the wording that reads Click here to see how the front holding gate works and a window will appear showing you how to adjust the front gate to accommodate your tubing OD.

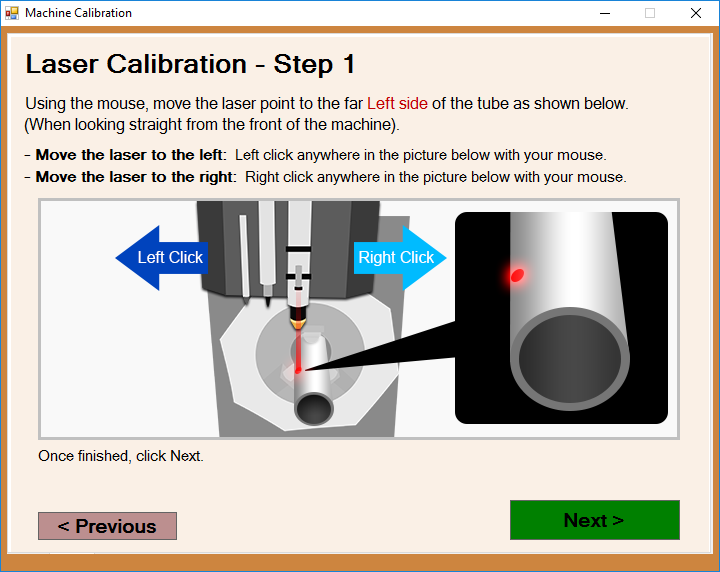

Laser Calibration - Step 1

- This page will prompt you to use the left and right buttons on your mouse to move the laser left and right until it touches the left most edge of the tubing.

- Next, press the next button to register the information with the software and continue.

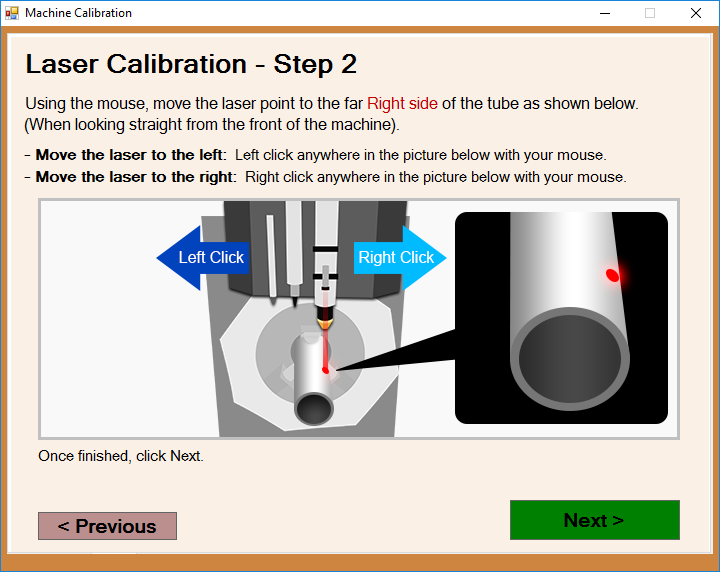

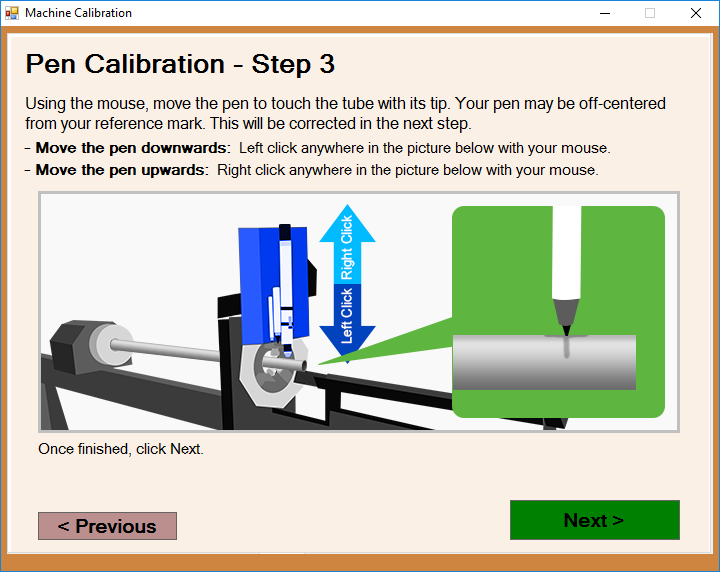

Laser Calibration - Step 2

- This page will prompt you to use the left and right buttons on your mouse to move the laser left and right until it touches the right most edge of the tubing.

- Next, press the next button to register the information with the software and continue.

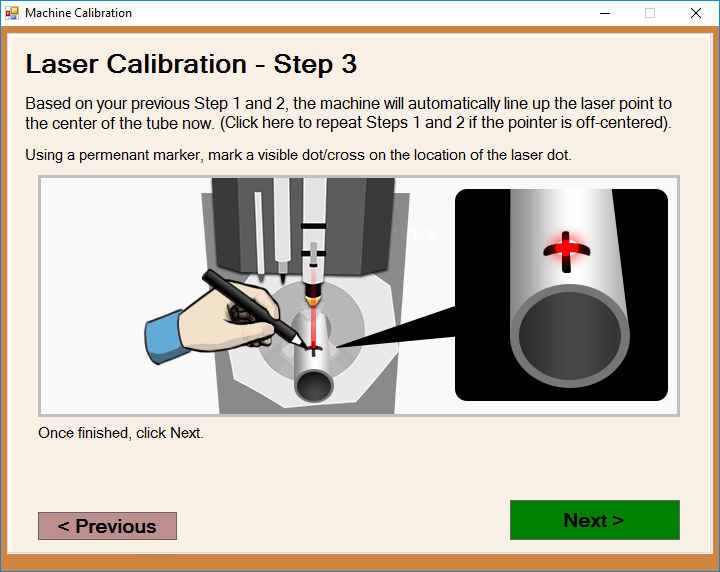

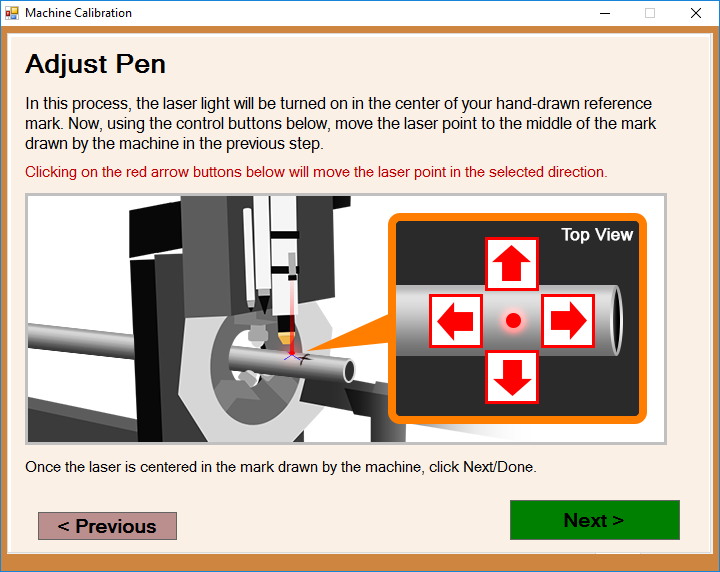

Laser Calibration - Step 3

- This page automatically use the information from the two previous steps and attempt to find the center of the tubing.

- If the location of the laser is not completely centered on the tube, repeat the previous steps to ensure an accurate calibration, then mark the absolute center with a marker.

- Then, click the next button to continue.

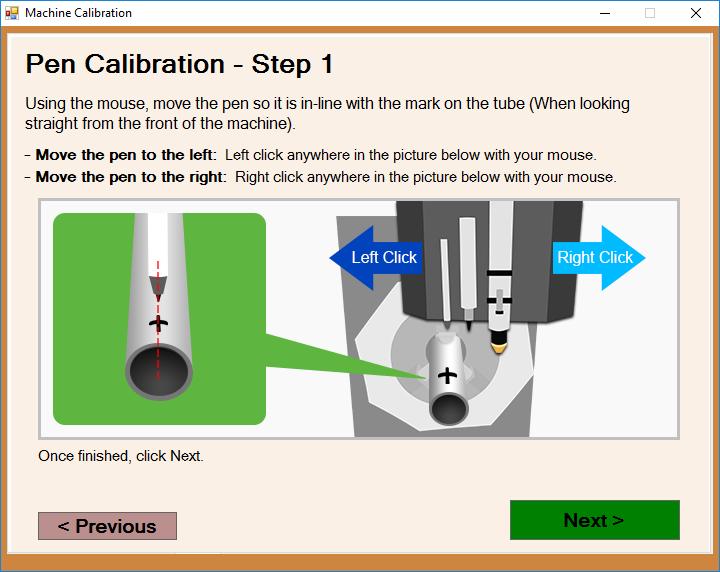

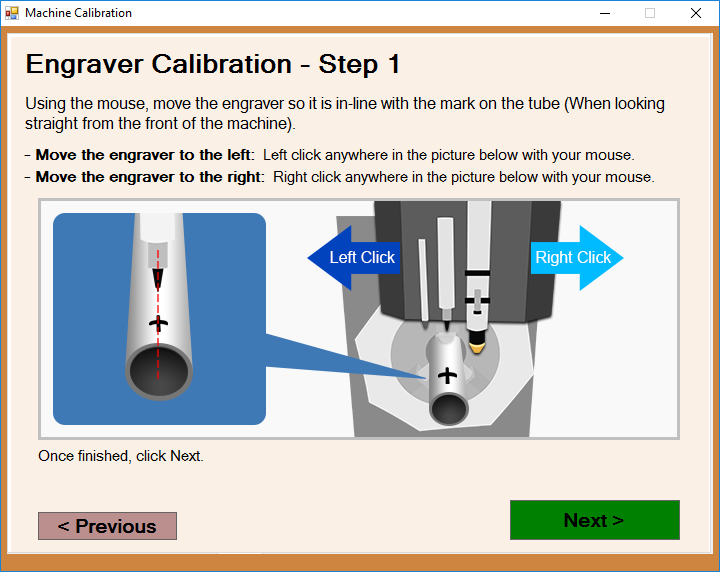

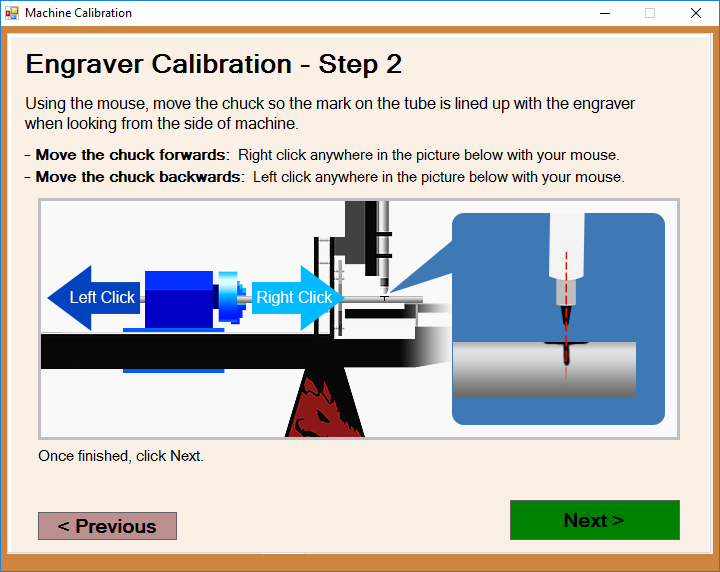

Engraver Alignment (X-Axis)

- This page will prompt you to use the Feed + and Feed - buttons to move the engraver along the length of the tubing (X-Axis) until it touches the mark you've created on the center of the tubing. Next, press the Feed 100% button to register the information with the software.

- Watch the video HERE

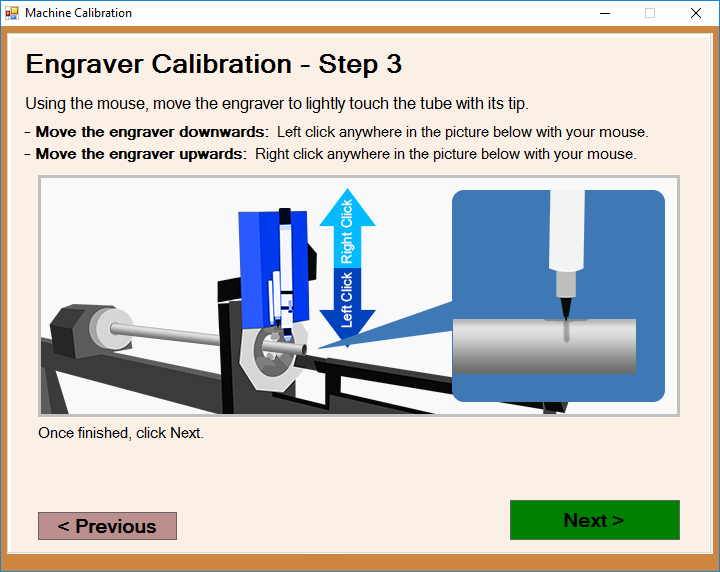

Engraver Height Adjustment

- This page will prompt you to use the Feed + and Feed - buttons to move the engraver up and down (Z-Axis) until it touches the center of the tubing. Next, press the Feed 100% button to register the information with the software.

- Watch the video HERE

Engraver Calibration: Verify

- This page will prompt you to make any adjustments to either the A, X or Z-Axes. Keep in mind that values entered are read in inches or millimeters based on your Options settings.

- The green lettering indicates that a positive number will move the adjustment left (A-Axis), forward (X-Axis) or down (Z-Axis), and a negative number will move the adjustment right (A-Axis), back X-Axis) or up (Z-Axis).

- If you'd like to change any of the previous steps, you can always press the Back' button and adjust them from there as well.

- Watch the video HERE

Torch Centering

- This page will prompt you to use the Feed + and Feed - buttons to move the torch left and right (A-Axis) to find the center of the tubing.

- You will have to click the Back button until you reach the Engraver Height Adjustment page to raise the toolset for this step. Then, press next to return to the Torch Centering page and use the Feed + and Feed - buttons to move the torch to the center.

- Next, press the Feed 100% button to register the information with the software.

- Watch the video HERE

Torch Alignment (X-Axis)

- This page will prompt you to use the Feed + and Feed - buttons to move the torch along the length of the tubing (X-Axis) until it touches the mark you've created on the center of the tubing. Next, press the Feed 100% button to register the information with the software.

- Watch the video HERE

Torch Height Adjustment

- This page will prompt you to use the Feed + and Feed - buttons to move the torch up and down (Z-Axis) until it touches the center of the tubing. Next, press the Feed 100% button to register the information with the software.

- Watch the video HERE

Torch Calibration: Verify

- This page will prompt you to make any adjustments to either the A, X or Z-Axes. Keep in mind that values entered are read in inches or millimeters based on your Options settings.

- The green lettering indicates that a positive number will move the adjustment left (A-Axis), forward (X-Axis) or down (Z-Axis), and a negative number will move the adjustment right (A-Axis), back X-Axis) or up (Z-Axis).

- If you'd like to change any of the previous steps, you can always press the Back' button and adjust them from there as well.

- Watch the video HERE