Difference between revisions of "SolidWorks"

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

If you have just recently purchased the SW module and have not yet registered the plugin, please do so by following the instructions on the [[Bend-Tech SW Module Installation]]. | If you have just recently purchased the SW module and have not yet registered the plugin, please do so by following the instructions on the [[Bend-Tech SW Module Installation]]. | ||

| − | Things to | + | '''Things to Know''': |

*This tutorial will step you through the process of exporting a file from SolidWorks and importing it into Bend-Tech. As you walk through this tutorial, procedures are designed based on your knowledge of earlier procedures. Because of this, it is very important that you carefully step through this guide, understanding everything along the way. | *This tutorial will step you through the process of exporting a file from SolidWorks and importing it into Bend-Tech. As you walk through this tutorial, procedures are designed based on your knowledge of earlier procedures. Because of this, it is very important that you carefully step through this guide, understanding everything along the way. | ||

| Line 20: | Line 20: | ||

| − | ===SolidWorks=== | + | ===SolidWorks Importing=== |

1. To be able to go through this tutorial, you must have a completed SolidWorks part file available. If not, create a part in SolidWorks™ and come back to this tutorial before continuing on. | 1. To be able to go through this tutorial, you must have a completed SolidWorks part file available. If not, create a part in SolidWorks™ and come back to this tutorial before continuing on. | ||

Latest revision as of 15:10, 6 December 2019

If you have just recently purchased the SW module and have not yet registered the plugin, please do so by following the instructions on the Bend-Tech SW Module Installation.

Things to Know:

- This tutorial will step you through the process of exporting a file from SolidWorks and importing it into Bend-Tech. As you walk through this tutorial, procedures are designed based on your knowledge of earlier procedures. Because of this, it is very important that you carefully step through this guide, understanding everything along the way.

A few key items need to be covered before starting the step-by-step instructions of the tutorial. It is very important you completely understand these items:

Centerline & Apex:

Centerline: In the Bend-Tech environment we are working exclusively with the centerline of a part, as compared to the inside or outside.

Apex: The bend locations are defined exclusively with the apex. Our definition of apex is the intersection of the straight tubes as if there wasn’t a radius.

Create Parts: It is possible to create parts in the single part and assembly interfaces of Bend-Tech SW, however, this guide focuses on using part geometry within SolidWorks™ to export into Bend-Tech SW.

Installation: You must have both SolidWorks™ and Bend-Tech SW loaded on the same computer. If installed correctly, you should find a menu selection in SolidWorks™ labeled Bend-Tech. This menu will only be available in SolidWorks™ Part mode and will not be seen in the Assembly mode of SolidWorks™.

Bend-Tech SE vs. SW: Bend-Tech SW contains all the functionality and features of Bend-Tech SE, as well as the ability to import parts directly from SolidWorks™. Any information available for Bend-Tech SE also applies to Bend-Tech SW.

SolidWorks Importing

1. To be able to go through this tutorial, you must have a completed SolidWorks part file available. If not, create a part in SolidWorks™ and come back to this tutorial before continuing on.

2. To import a part from SolidWorks™, ensure that both SolidWorks™ and Bend-Tech are both open and running.

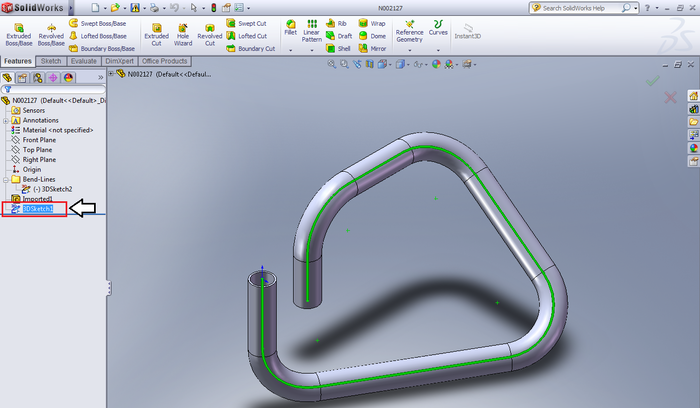

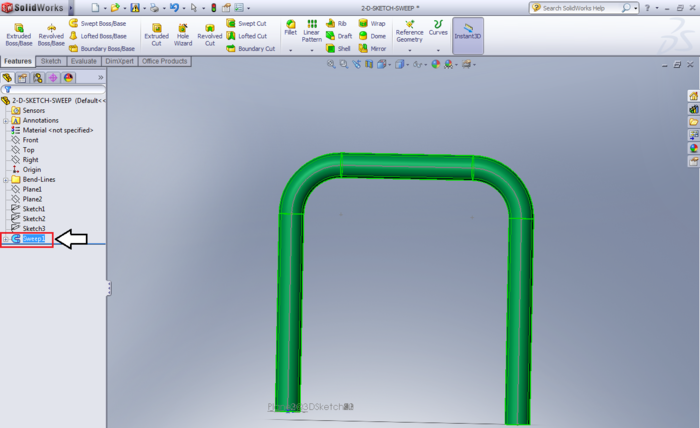

3. In SolidWorks™, select either the 3D Sketch or Sweep of the part from the Features list on the left side of the frame as shown below. Once selected the sweep or 3D sketch name will be highlighted in blue.

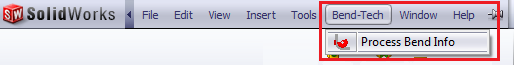

4. Once the sketch or sweep line has been selected, go up to the top left of the SolidWorks window and place your cursor over the right pointing arrow to access the menu bar. In the menu bar, go to the Bend-Tech option and click on Process Bend Info.

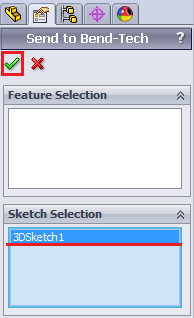

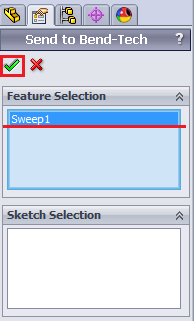

5. Once Process Bend Info has been selected, the Send To Bend-Tech panel will be opened on the left side of the window. Depending on what kind of feature you selected (3D Sketch or Sweep), it will be shown in either the Feature Selection or Sketch Selection box. Make sure that the listed feature is correct, click on it to select it, then click the green check button.

Part Definition

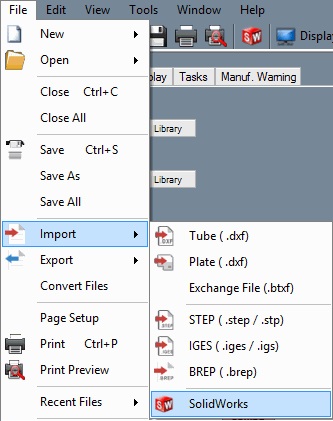

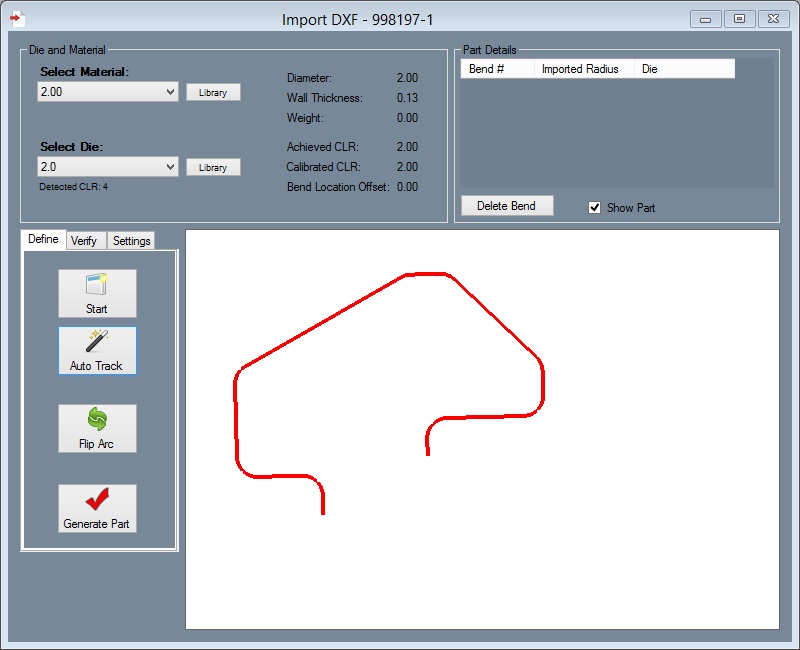

1. Now, back in the Bend-Tech window it's time to bring the part information into Bend-Tech. To do so, either click on the SolidWorks™ icon in the icon toolbar or go to File --> Import --> SolidWorks. This will bring the part information into a Bend-Tech Import Part window.

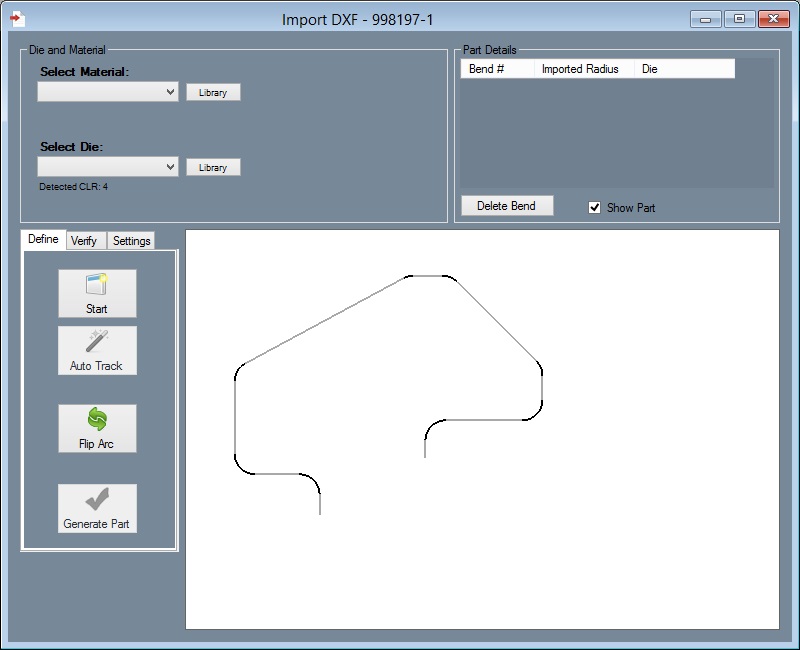

2. A skeleton frame of the part will be shown in the part display window. Each section will have its own PickPoint. Straight sections have a gray outlined point and arcs/circles will have black outlined points.

"Note: From now on, only one part will be shown in the images. Both parts (Exported using 3D Sketch or Sweep) are imported using the same methods."

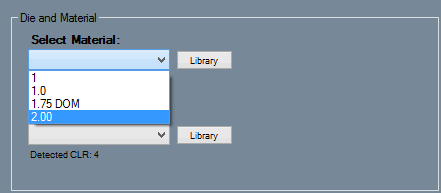

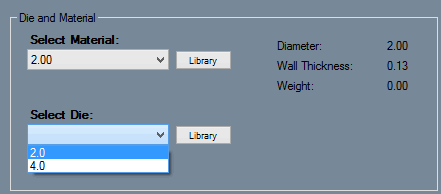

3. Select a material from the "Select Material" drop down menu in the top corner. Since we are not working with the same part, you must choose a material that will work properly with your part design. If necessary, click the library button to open the "Tube/Pipe Library" to add or adjust any materials.

4. Next, select a die from the "Select Die" drop down menu. Notice how the imported CLR is listed directly below this drop down menu. Since this specific part has a 2 inch CLR, a 2.0 CLR die has been selected. Choose a die that is either close to the imported CLR or a die that you will be using when creating this part later on.

Defining The Part

- There are two different ways to define parts. One way is to click on each section to define them. The other is to auto-track the part. This tutorial will do both, starting with manually clicking each section.

1. Click the "Start" ![]() button in the "Define" tab.

button in the "Define" tab.

2. Now click on each section that you want to include.

- (Note) Once a section has been defined, it will be highlighted in red. You may need to rotate, move, or zoom in on the part to see each section's PickPoint properly. The part preview can be rotated by clicking and holding the right mouse button and moving the cursor around. Move the part by clicking and holding the scroll wheel button or both mouse buttons and moving the cursor around. The part preview can be zoomed in or out by using the scroll wheel - scroll up to zoom out and scroll down to zoom in.

- These lines represent the centerline of the part.

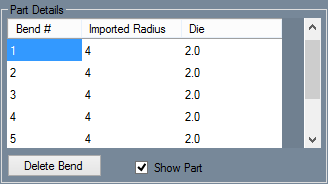

3. Once each section has been defined, click the "Generate Part" ![]() button in the "Define" tab.

button in the "Define" tab.

- This will bring the part information into the Part Details chart. Each bend will have its own entry.

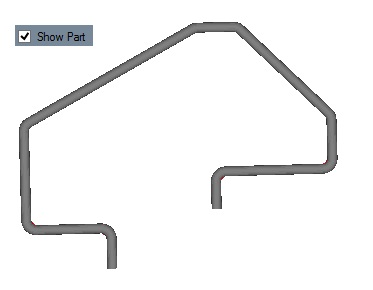

4. Check the "Show Part" check box to view the part in the material that was chosen earlier.

5. Now, repeat the defining process again using the Auto Track method. Click the "Start button" ![]() again and click on any of the part sections. Now click on the "Auto Track"

again and click on any of the part sections. Now click on the "Auto Track" ![]() button. The entire part should be defined automatically.

button. The entire part should be defined automatically.

6. Click the "Generate Part" ![]() button again to bring the part information into the Part Details chart.

button again to bring the part information into the Part Details chart.

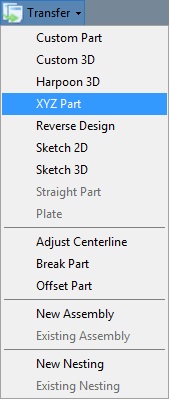

7. Now, send the part to a part design interface. Click the "Transfer" drop down menu on the "Main Menu" taskbar.

8. Select "XYZ Part" from the list.

The import process is complete.