Difference between revisions of "DragonA400 Tips & Hints"

(→Engraver Tip Replacement) |

|||

| Line 35: | Line 35: | ||

==Engraver Tip Replacement== | ==Engraver Tip Replacement== | ||

| − | [[File:Engraver_Tip_Replacements2. | + | [[File:Engraver_Tip_Replacements2.jpg]] |

Sometimes, regardless of preventative maintenance measures taken, the engraver tip will be in need of replacement. In this case, this engraver can be purchased at the link available here. | Sometimes, regardless of preventative maintenance measures taken, the engraver tip will be in need of replacement. In this case, this engraver can be purchased at the link available here. | ||

https://www.mscdirect.com/product/details/92370220 | https://www.mscdirect.com/product/details/92370220 | ||

Revision as of 14:34, 10 November 2017

This page will discuss tips and hints that we've found useful for DragonA400 users who experience various difficulties with their machine and/or components.

Contents

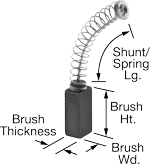

Carbon Grounding Brush Replacement

If you've put a significant amount of hours on the Dragon Machine, there may come a time when the carbon grounding brushes will need replacing. These can be purchased at the link available here. (Part ID# 65705K39)

https://www.mcmaster.com/#65705K39

Plasma Gas Selection

- Select the Plasma Gas Selection Information link for detailed information showing what advantages and disadvantages there are to working with gasses in your plasma torch.

Air Filter System

Do I need a separate air filter for my air plasma system? The cut quality, performance, and consumable life of any air plasma system are directly impacted by the quality of the air going into it. Not only is it important to make sure you have enough air; you also need to make sure the air you have is clean and dry. This is especially important in areas with humid weather, as this excess moisture will easily make its way into your air compressor tank and air lines. If this should be the case, we suggest draining your tank at least once a day or better yet, installing an automatic drain system. In addition, you may want to add a second filter (in addition to the filter already inside your plasma unit) at least 20 feet downstream of the compressor, to help collect some of this moisture. If you plan to use your system a lot – in a production environment, for example – or live in an area with extreme humidity, then you may need to use a refrigerated air dryer or desiccant filter system to remove moisture.

Marker Slippage/Inconsistent Placement

Sometimes the markers placed in the marker holder slip freely and fall out of the holder. Other times they get jammed up into the holder and are impossible to remove. We recommend a black or silver Sharpie for this. If the silver Sharpie still slips out of its holder, wrap the marker in tape (we use duct tape, but any tape will do) to ensure that it is held securely in the marker holder.

Or

Simply flip the head of the marker holder to the other end of the cylinder and the opposing end should accommodate both black and silver Sharpies.

Marker Revival

Sometimes the markers will dry out because they are marking close to a cut zone where the tubing is still hot from the plasma. This can dry out your markers in record time. To bring your dried out marker back to life, dip the tip in some rubbing alcohol and it will work as good as new. It is also smart to make sure that your tubing is wiped down before running the stick to make sure that the grease doesn't inhibit the marker's ability to show up well on the surface.

Engraver Maintenance

To ensure that your engraver tip lasts as long as possible, we suggest that you invest in an airline oiler and install it in your air line as shown here.

Engraver Tip Replacement

Sometimes, regardless of preventative maintenance measures taken, the engraver tip will be in need of replacement. In this case, this engraver can be purchased at the link available here.