Custom Part

Bend-Tech 7x Wiki :: Custom Part

Custom parts can be created by supplying length, rotation, and angle values.

Selection

To create a Custom Part:1.) Go to the File menu, select New, then select Tube. In the Create New menu, click on the Custom Part option.

2.) Click the New Part icon and select the Custom Part option in theCreate New menu.

...OR

3.) Select the Custom Part option from the task menu that appears when the software starts up or when all designs are closed.

Design

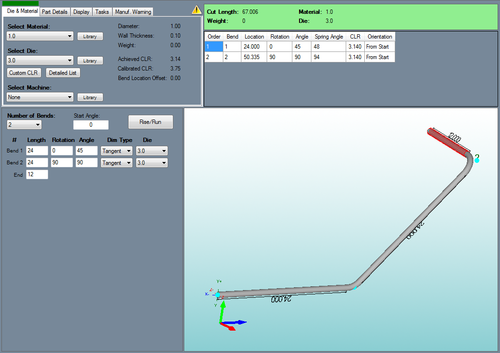

Once 'Custom Part' has been clicked, a new custom part window will open. If a default die and material have not been set, a die, material, and/or machine must be chosen before designing the part. If necessary, choose a material and die in the Die and Material tab. Once a die and material have been chosen, the custom part design section will be available to use.

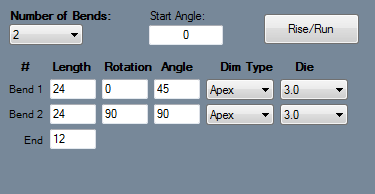

The number of bends in the part can be chosen from the 'Number of Bends:' drop down menu. Up to 50 bends can be added to a part.

To change the starting angle of the part, enter a value in the 'Start Angle:' field.

Below all these options, the length, rotation, and angle values can be entered for each part's bend and the end length. To define length, rotation, angle, or end values, just enter a number into any of the fields.

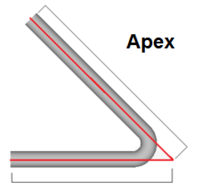

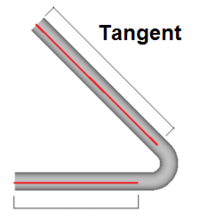

Each bend will have a Dim Type and Die drop down menu. Dim Type will determine how the part length will be measured for that bend. To choose a dimension type, click the drop down menu and select either Apex or Tangent. To change all the dimension types to single type, select the desired dimension type in the Dim Type for the first bend, then hit the enter key. Apex will measure to the outside intersection (apex) of the bends two legs. Tangent will measure to the edge of the bends, the tangents, so no bent material will be included in the measurements. Different dies can be selected for each bend by either clicking any of the 'Die' drop down menus and selecting a die/Custom CLR.

The Rise and Run button can be used to generate length and angle values based on the rise and run of a specific length of tubing. First place the cursor in and of the length fields from the second bend and onward.

Click on Rise and Run ![]() to open the tool. Enter the rise and run values in the fields and the calculated length and angle values will be generated below. Check the Over 90 Degree Bend check box if the measurements are for a length with a bend that exceeds 90 degrees. Click the Use Values button

to open the tool. Enter the rise and run values in the fields and the calculated length and angle values will be generated below. Check the Over 90 Degree Bend check box if the measurements are for a length with a bend that exceeds 90 degrees. Click the Use Values button ![]() to bring in the length value for the current bend and the bend angle for the previous bend.

to bring in the length value for the current bend and the bend angle for the previous bend.