Exhaust Tutorial II

UNDER CONSTRUCTION: THANK YOU FOR YOUR PATIENCE

This tutorial is designed to walk the user through the steps in making an exhaust system out of bent parts in the Exhaust interface. For initial and secondary assistance on the Exhaust interface, see Exhaust Design and Exhaust Tutorial.

Contents

Things To Know

- This tutorial is designed to walk the user through creating an exhaust system in the Exhaust Design interface. As you go through this tutorial, later procedures will assume that you understand all earlier procedures. Because of this, it is very important that you carefully step through this guide, understanding everything along the way and following all steps in order.

- A few key items need to be addressed before starting the step-by-step instructions of this tutorial. It is very important for Bend-Tech users to completely understand these items:

- 1) Center Line & Apex

-

- Center Line: In the Exhaust Design environment we are working exclusively with the center-line of a part, as compared to the inside or outside.

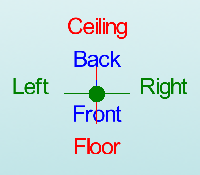

- 2) Locational Orientation

-

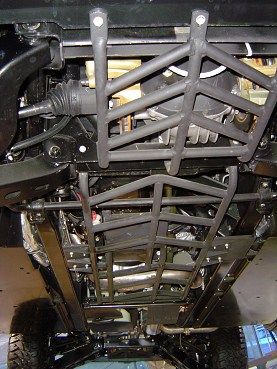

- Designing in the Exhaust Design interface seems to work the best if users imagine they are standing underneath the vehicle at a 45 degree angle, looking upwards. This way left is left and right is right. Take a minute and examine the Tri-Star to get your orientation.

- Notice how the truck in the picture is setup with the same orientation.

- 3) Defining Parts

-

- It is possible to create parts in the template and custom part interfaces, however, starting out this way tends to get confusing for new users of the software. It appears that there is a higher level of success with customers who start out designing parts directly in the assembly interface.

Start Up

1) Start by double clicking the "Bend-Tech 7x" icon to start up the program.2) Select the "Exhaust" icon ![]() in the Task Menu under the "Create New" section to open the Exhaust interface. The window that opens should be labeled [Exhaust Design – 1].

in the Task Menu under the "Create New" section to open the Exhaust interface. The window that opens should be labeled [Exhaust Design – 1].

3) For the purposes of this tutorial, click the "Maximize" button ![]() at the top right of the Exhaust Design window.

at the top right of the Exhaust Design window.

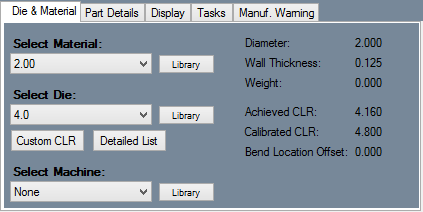

4) For the purposes of this tutorial. The "Die & Material" tab is located in the upper left corner of the window. Select the "2.00 Material" and "4.0 Die" as seen here.

Changing the "Grid Spacing"

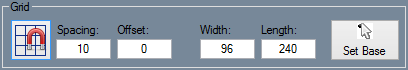

1. Start by selecting the "Spacing:" value field and changing the value to "6".

- This will give the user more control and accuracy when creating their lengths of pipes in the display area.

2. Also, select the "Width:" value field and change the number to "240" to make our grid a complete square.

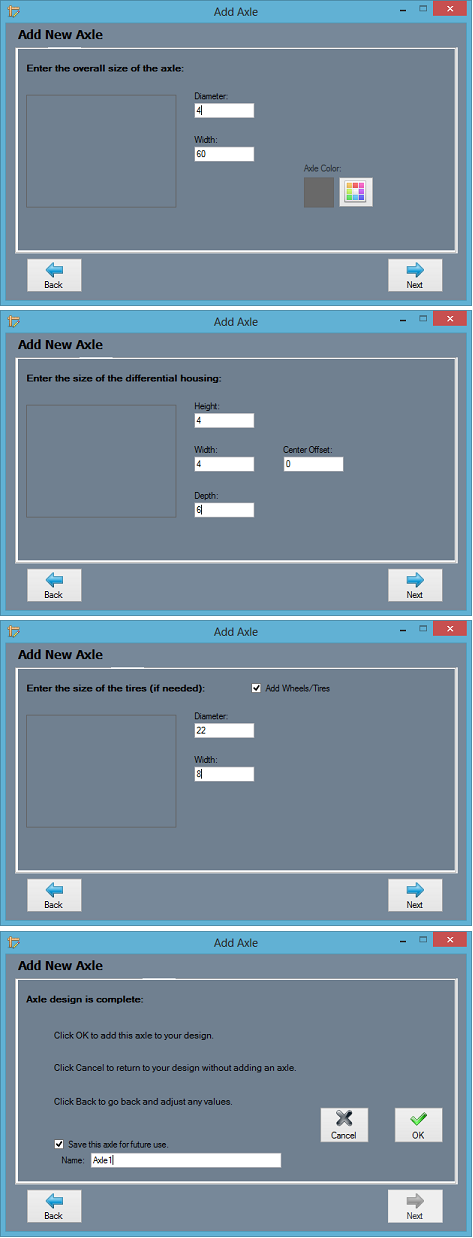

Creating an Axle

1. Select the "Axle" ![]() button and the "Add Axle" window will open.

button and the "Add Axle" window will open.

3. Type "4" in the "Diameter:" value field to set the axle diameter to 4 inches.

4. Type "60" in the "Width:" value field to set the distance from the axle's end to end.

6. Type "4" in the "Height:" value field, "4" in the "Width:" value field, and "6" in the "Depth:" field to create the differential housing.

8. Select the check box that indicates that you'd like to add tires, type "22" in the "Diameter:" value field and "8" in the "Width:" value field to create tires on the axle.

10. Save the part as "Axle1" and select the "OK" ![]() button to finish the part.

button to finish the part.

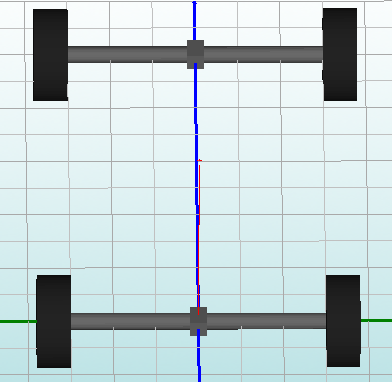

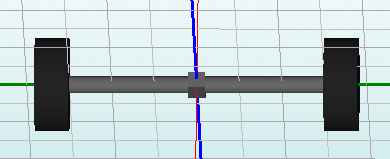

11. Place the part in the display area as show here.

12. Place the center of a duplicate of the axle exactly two spaces (12 inches) away from the edge of the grid as seen below.

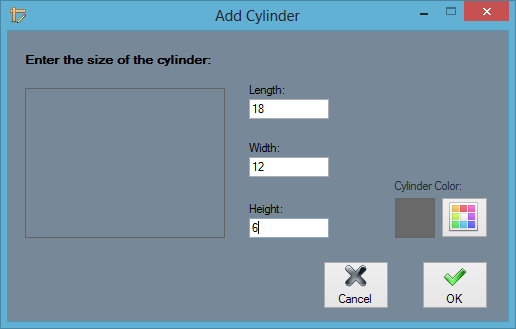

Creating a Catalytic Converter

1. Select the "Cylinder" ![]() button and the "Add Cylinder" window will open.

button and the "Add Cylinder" window will open.

2. Type "18" in the "Length:" value field, "12" in the "Width:" value field, and "6" in the "Height:" field to create a cylindrical catalytic converter model.

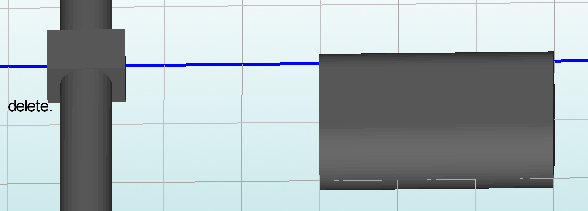

3. Select the "OK" ![]() button and place the part in the display area "6" inches to the left of the blue line and "14" inches behind the front axle(about 2 1/2 squares on the grid). (See picture below.)

button and place the part in the display area "6" inches to the left of the blue line and "14" inches behind the front axle(about 2 1/2 squares on the grid). (See picture below.)

Creating an Offset Part

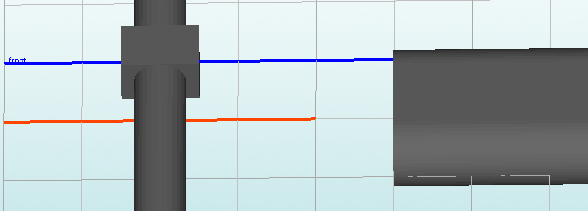

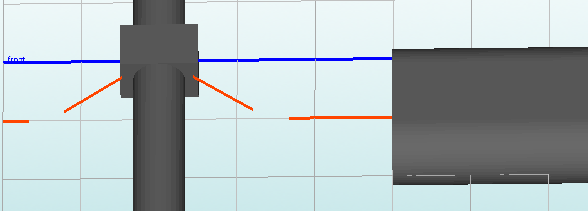

1. Select the "New Section" button and place a length of pipe "24" inches long which runs directly through the front axle at 6 inches parallel to the blue line. (See below.)

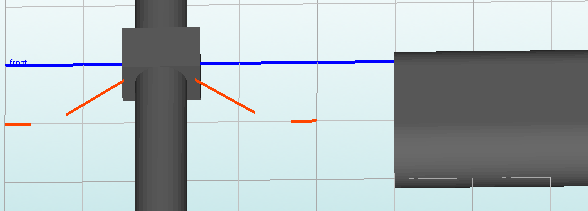

2. Next, select the "Offset" ![]() button, select the 2 foot section, and create an offset part that bends up and over the axle.

button, select the 2 foot section, and create an offset part that bends up and over the axle.

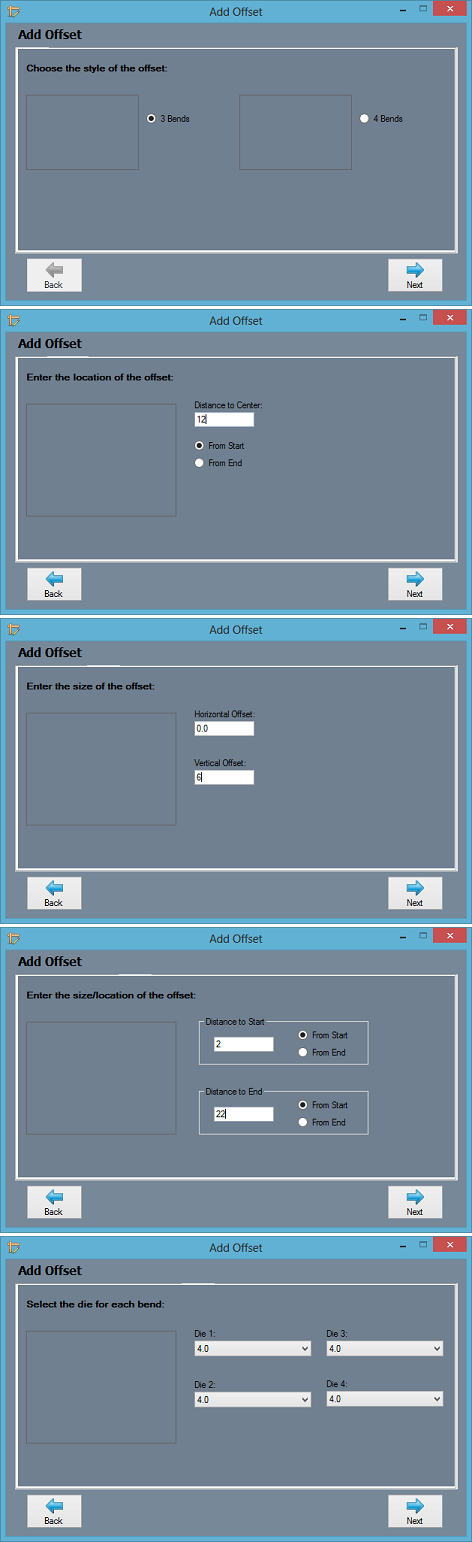

3. Select the "3 Bends" option and select the "Next" ![]() button.

button.

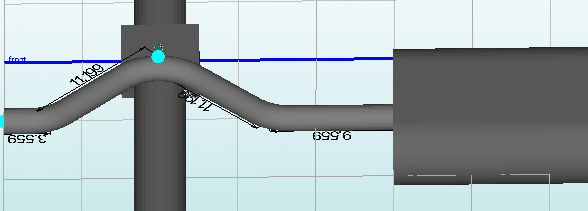

4. Since the section is 24 inches, type "12" in the "Distance to Center:" value field for the location of the center bend.

6. Type "6" in the "Vertical Offset:" to set the distance the center line of the part will move vertically off of it's plane.

8. Type "2" in the "Distance to Start:" value field and "22" in the "Distance to End:" value field to set the location of the offset's beginning and end.

10. Leave all the dies at "4.0" and select the "Next" ![]() button.

button.

Defining/Deleting/Re-defining

- (Note) At times, users will realize that their segments aren't supposed to be defined as a single part, while other times they'll need to additional segments to their already defined part.

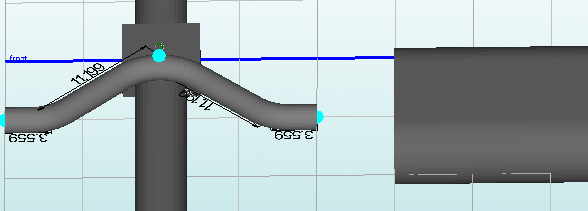

1. Select the "Define" ![]() button and click on each of the offset segments in succession to apply the material.

button and click on each of the offset segments in succession to apply the material.

- Doing this will supply the user with a parts list in the "Defined Parts:" section located in the lower left of the screen. From there, users can change the die that will be used for any defined part available and for any bend within those defined parts.

2. Now, select the "New Section" ![]() button and fill in the remaining "6" inches from the offset part to the catalytic converter.

button and fill in the remaining "6" inches from the offset part to the catalytic converter.

3. Since that part is "undefined" and will NOT become defined as part of the offset segment with a simple click, select the "Delete" ![]() button next to "Define" and delete the offset part definition before you are able to define it along with the new segment.

button next to "Define" and delete the offset part definition before you are able to define it along with the new segment.

4. Now, select the "Define" ![]() button and click on each of the segments in succession as shown below.

button and click on each of the segments in succession as shown below.