Dragon Diamond Notch Bridging Tutorial

Dragon Diamond Notch Bridging Tutorial

Things To Know

- This tutorial will step you through the process of creating a straight design in Bend-Tech Dragon CAD, add a notch cutout and show you where to take it next in order to add a notch bridge . As you walk through this tutorial, procedures are designed based on your knowledge of earlier procedures. Because of this, it is very important that you carefully step through this guide, understanding everything along the way.

Tutorial

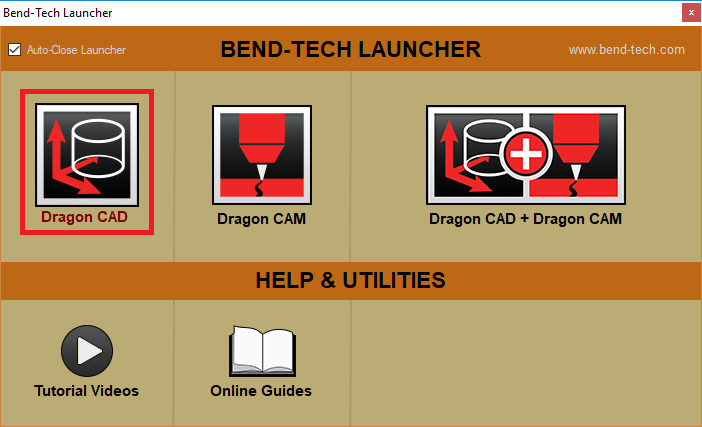

1. Start by opening up the Bend-Tech Launcher on your computer and select the Dragon CAD option so we can start our design process.

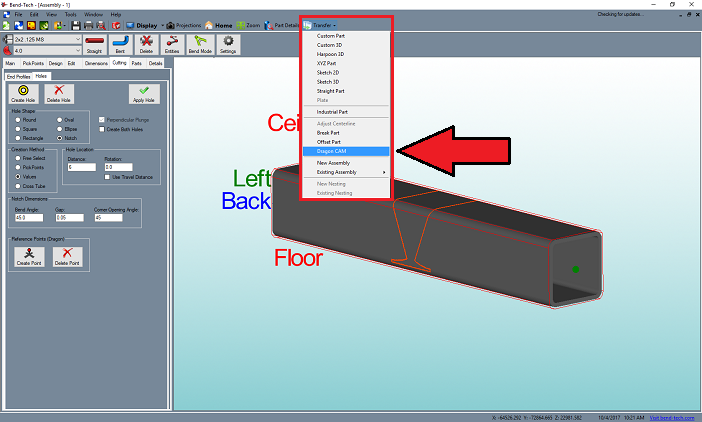

2. With the Task Menu screen open, select the Assembly designer option to begin drawing our part.

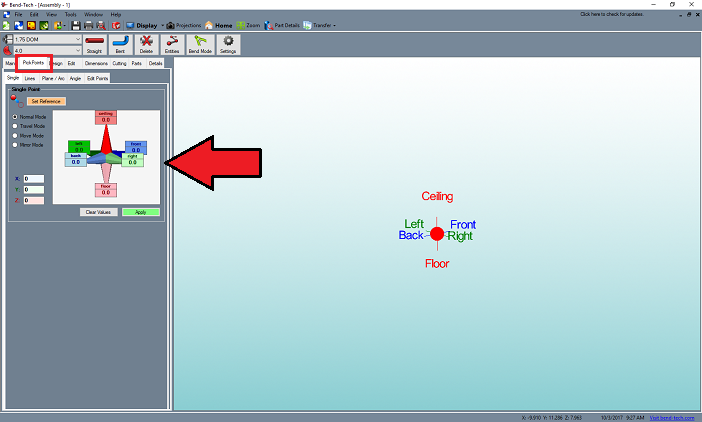

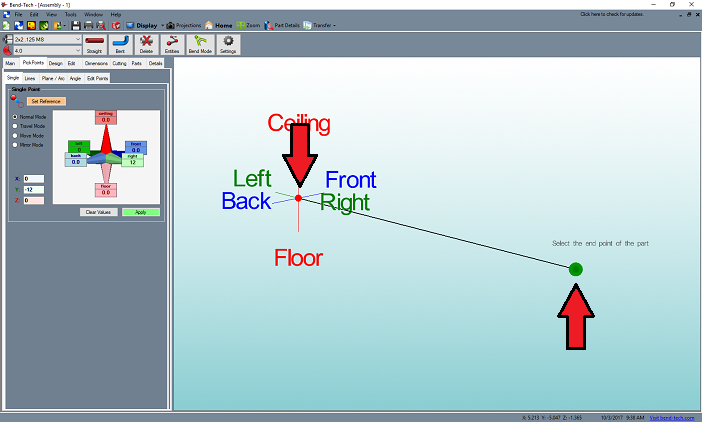

3. Maximize the screen here and select the Pickpoints tab. We will now create a single Pickpoint to indicate the length of a single part.

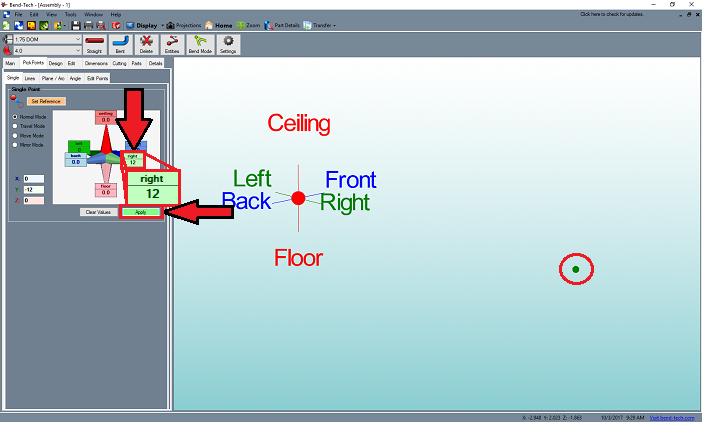

4. Select the Right entry field and type 12 into it to indicate a 12 inch part.

5. Click the Apply button to apply the point in the design.

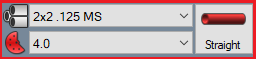

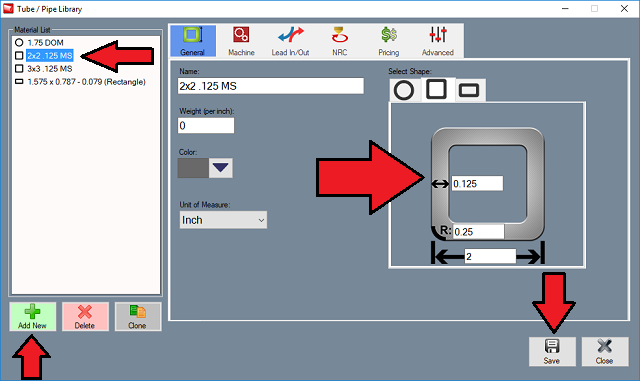

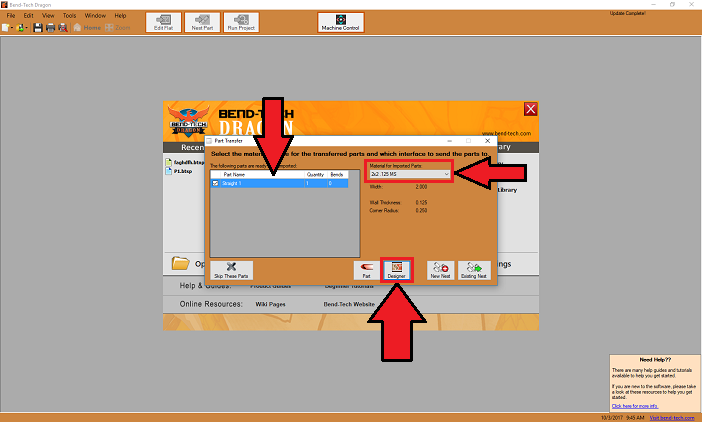

6. Select a Square OR Rectangular material from the material drop down list (the size of which is irrelevant). If you have not created one, you must first create one in the Tube/Pipe Library beforehand. This is available in the TOOLS tab at the top of your screen.

7. Once you have a square or rectangular material selected, click on the Straight button next to the material and die selection menus to indicate that we are drawing a straight part.

8. Then, click on the Tri-star in the display screen followed by our user-created point to draw our straight part.

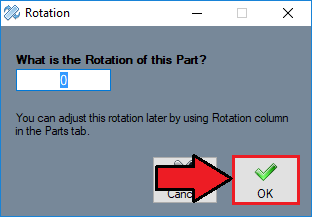

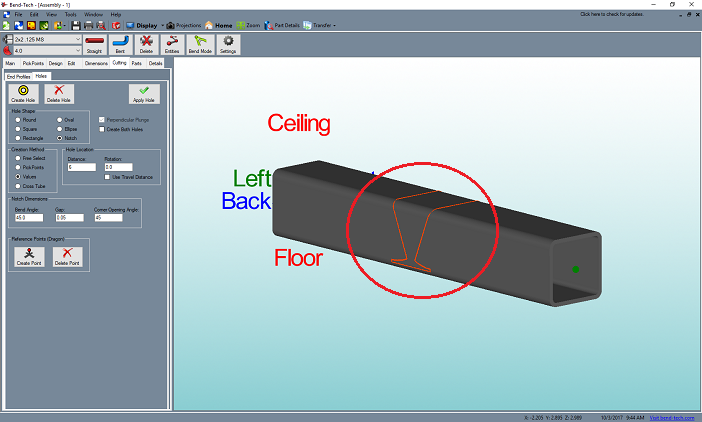

9. A window will appear asking if you'd like to indicate a rotational value for the part itself. Leave this value at 0 and click the OK button. Your part should now appear as a line in the display screen.

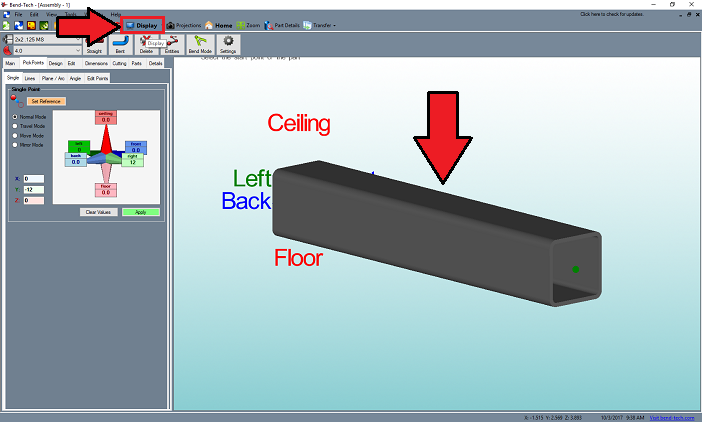

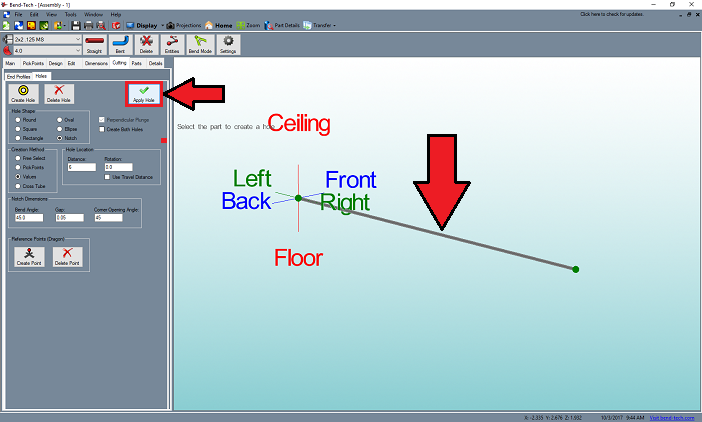

10. To view your straight part as a 3D rendering, click on the Display button from above.

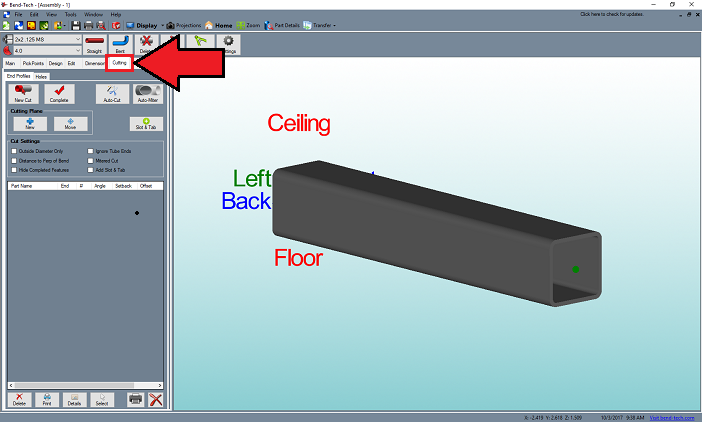

11. Then, click on the Cutting tab to access the options to create cuts and holes on your part.

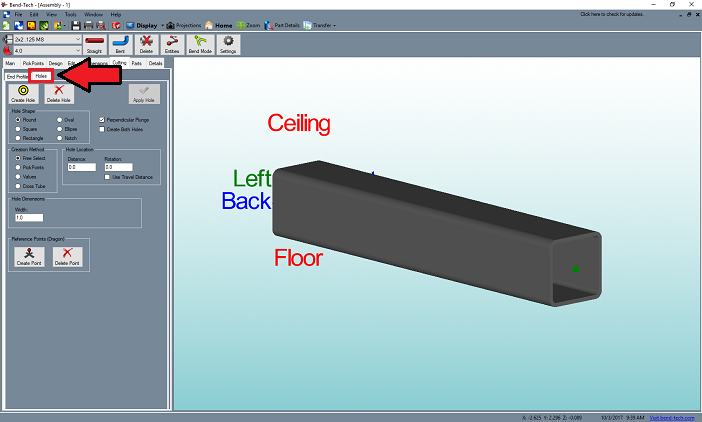

12. Select the Holes sub tab to access the options for making holes only.

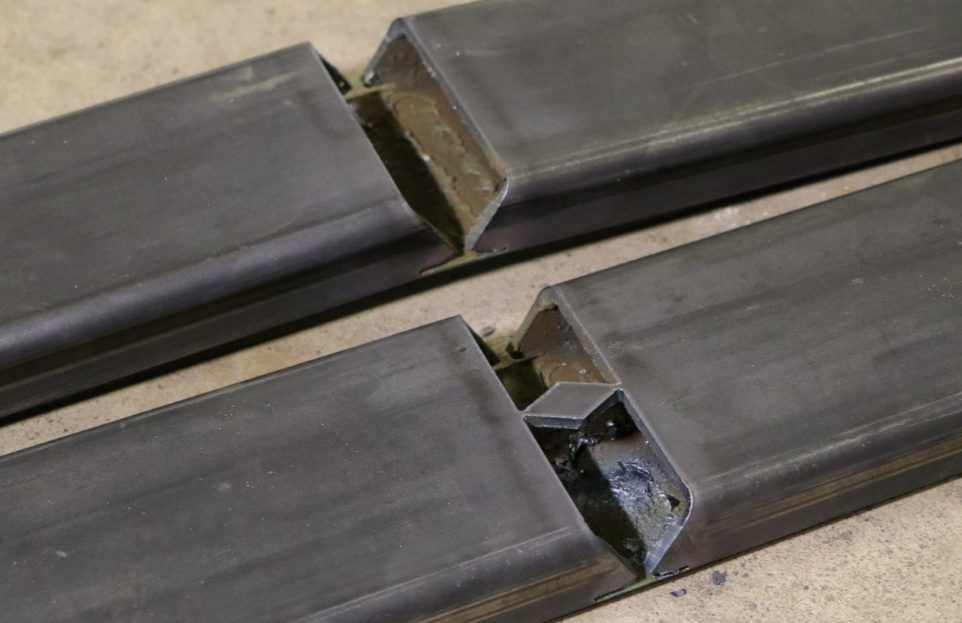

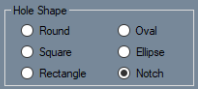

13. Under the Hole Type section, select the Notch option. NOTE: This is only available as a hole type for square or rectangular tubing.

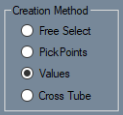

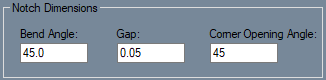

14. Under the Creation Method select the Values option. This indicates that the holes will be created based on the value you assign it. (Other creation methods include Pickpoints - in which 3 pickpoints are necessary for hole placement, Free Select - in which the hole will be placed wherever the user clicks in the design, and Cross Tube - in which case the user will need a intersecting tube created in the design and will first click the tube that will receive the notch followed by the FAR END of the cross tube intersecting it in order to place the hole.)