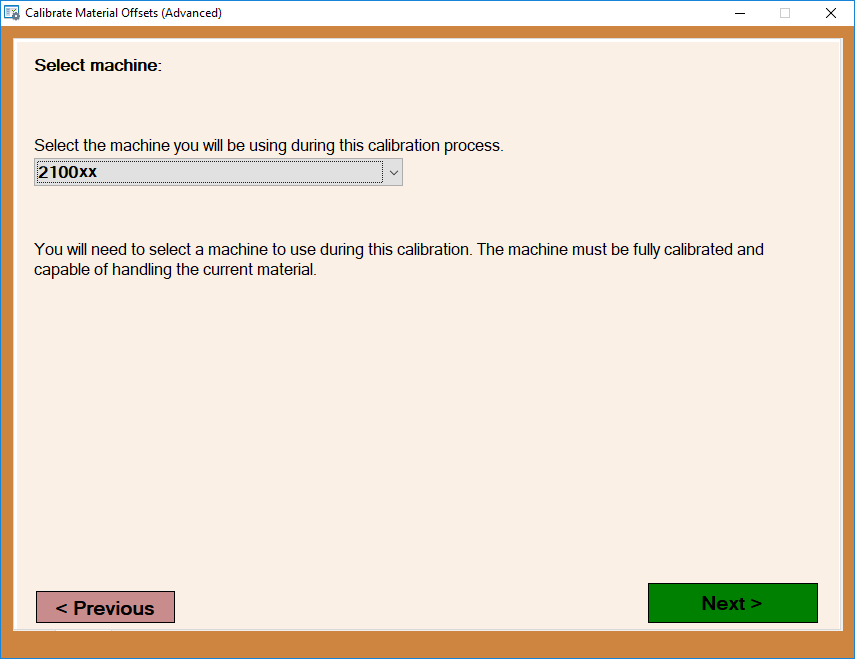

Dragon A400 Side Offsets Calibration

Dragon A400 Side Offsets Calibration

This calibration is no longer in its testing phase and is ready for use in Dragon A400 version 1.07.13.

This calibration is meant for Dragon A400 users experiencing differences in cutting height and side to side offsets due to front gate centering issues while running square and rectangular tubing only.

Contents

1.

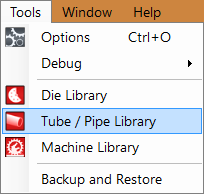

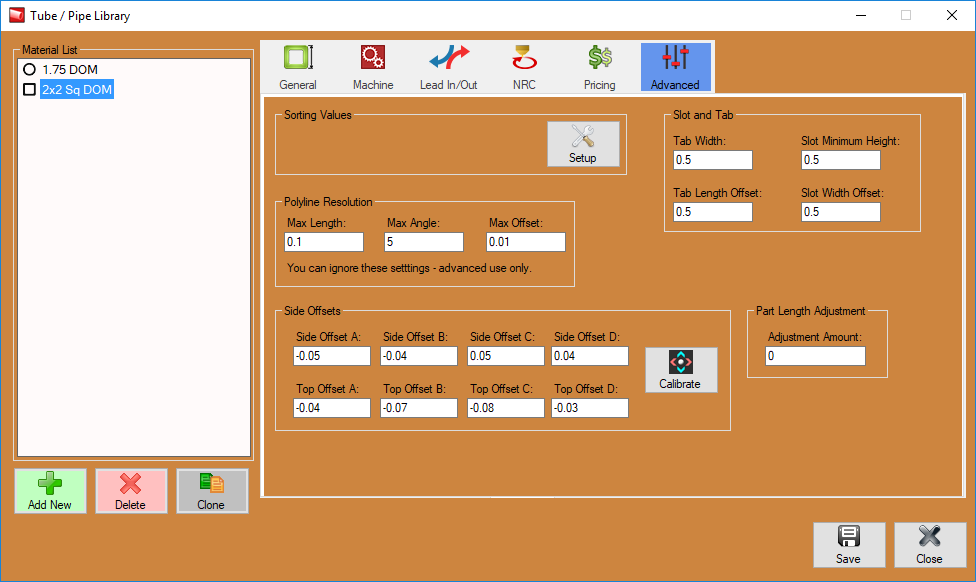

If you require a way to calibrate your torch height on all sides based on your tubing, the option is here for you located in the Tube/Pipe Library under the Advanced tab. You will have to select a square or rectangular tubing from the material list in order to change to the Advanced tab.

2.

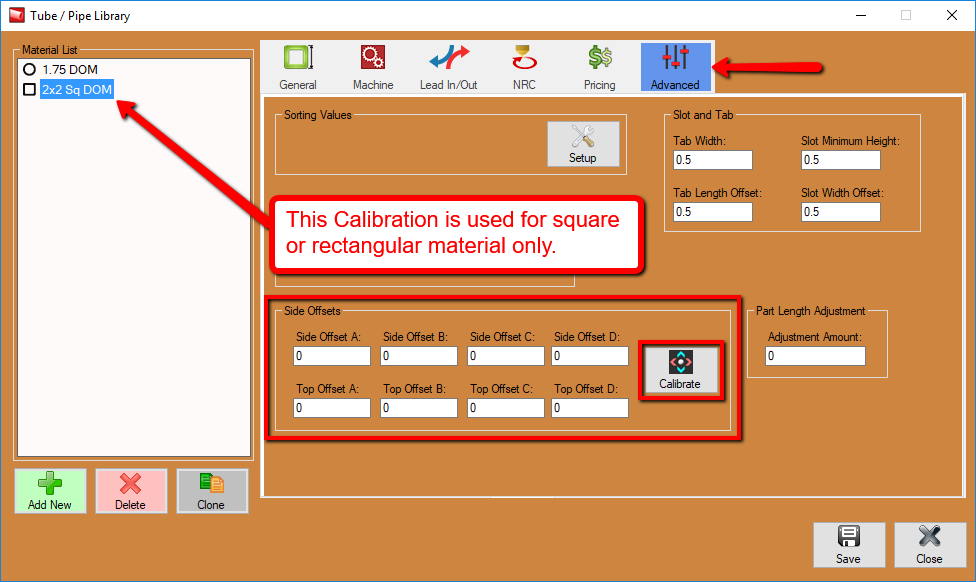

In the Advanced tab, select the Calibrate option under the Side Offsets section at the bottom of the window.

3.

The first screen is available to Disable any previously entered material side offsets (as an option) before continuing with the calibration. click Next to start the calibration process.

4.

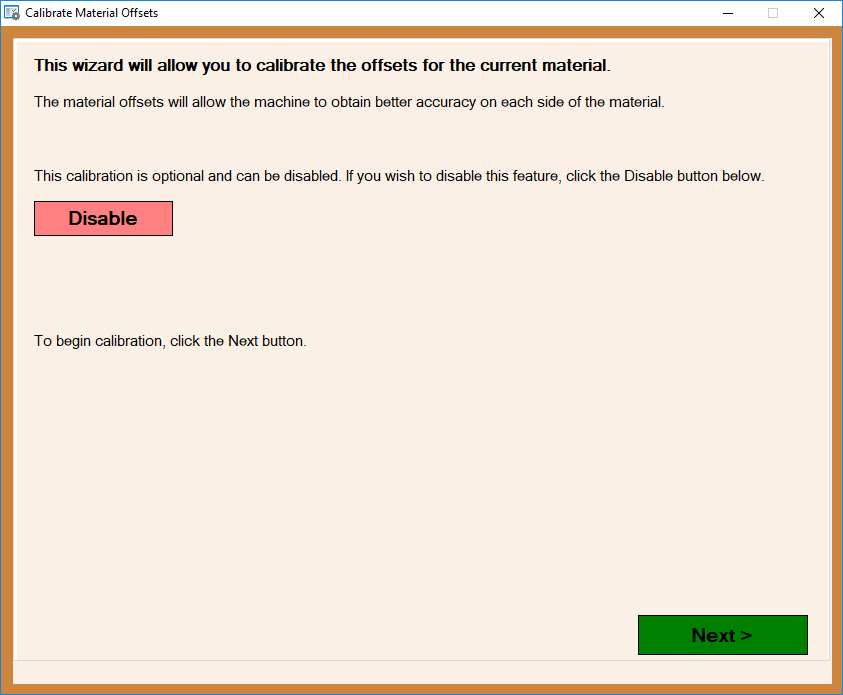

On this screen, you will be prompted to select your machine (usually named Factory Calibrated Machine or for its serial number) before continuing. Once the proper machine is selected, click the Next button.

5.

Now, ensure that your machine is turned on and click the Start Mach button on the screen to turn on the Mach 3 software, or, in the case that it is already turned on, the calibration screen will acknowledge this and continue to the next step in the calibration process.

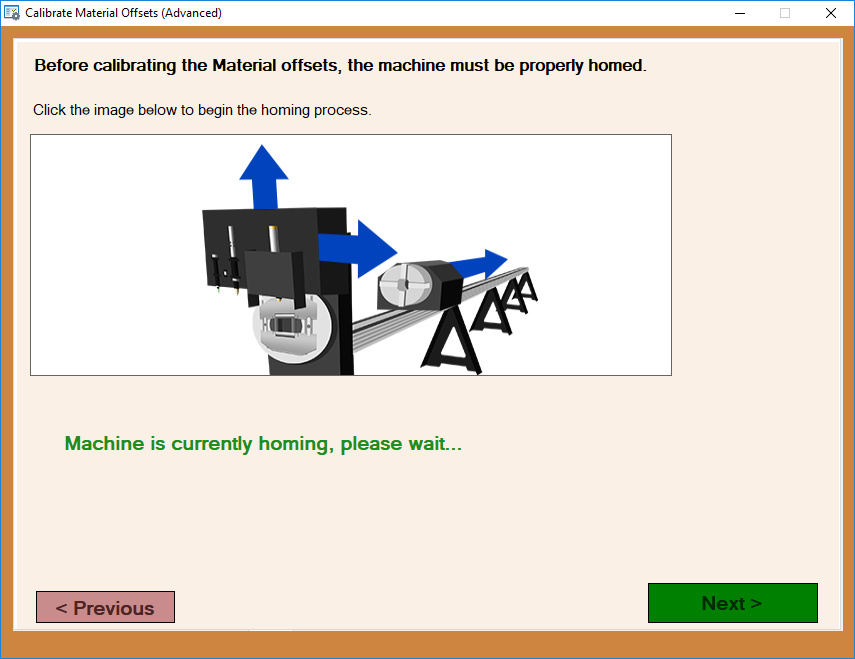

6.

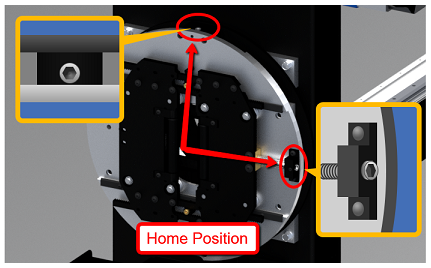

The calibration window will appear and instruct you to home your machine before continuing. Once it is completely home, the green lettering will disappear and you are free to click the Next button. IMPORTANT: Make sure the front gate is positioned to its HOME position before continuing.

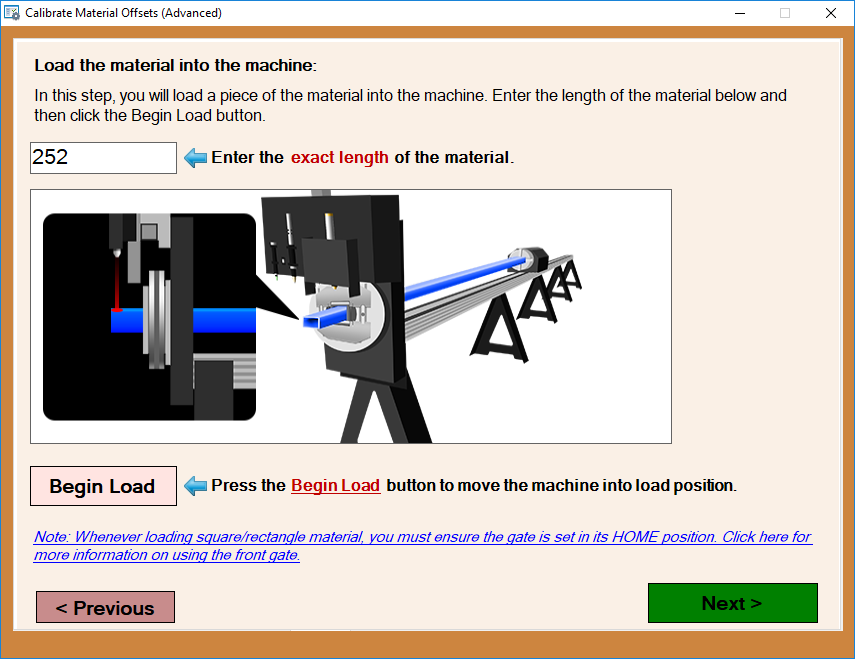

7.

Now, you will be prompted to indicate the length of the tubing by entering it into the provided value field, then click the Begin Load button to bring the chuck trolley to its load position for this length tube. Proceed to load the material and click the Next button once you've done so.

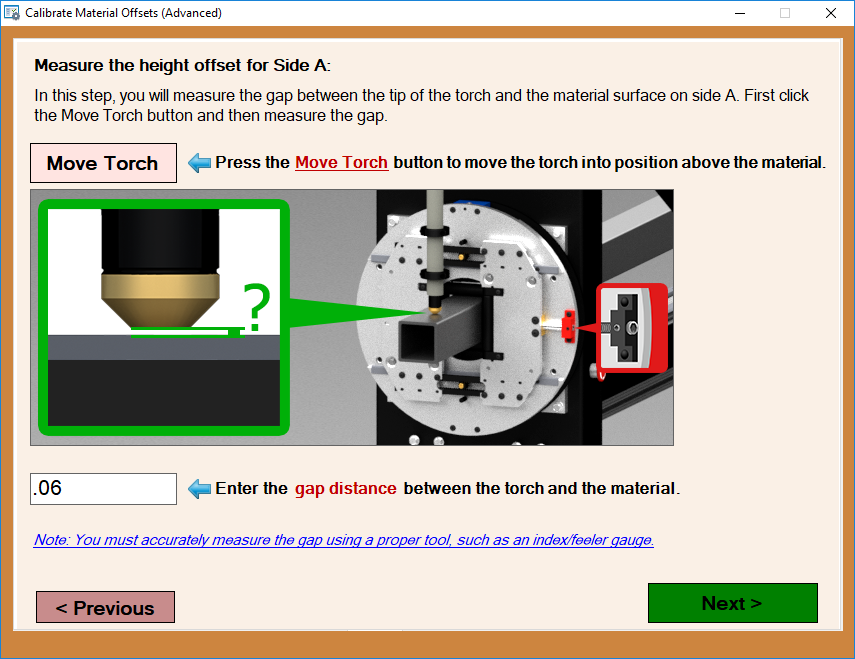

8.

Obtain a feeler gauge for the following steps. For our purposes, we will refer to this top side of the material as (Side A). Select the Move Torch button in this window and proceed to using the feeler gauge to judge the exact height of the torch tip from the top dead center of the material's surface. Indicate the gap distance in the value field provided and select the Next button.

The torch should now raise and the chuck will rotate exactly 90 degrees for use on the next step.

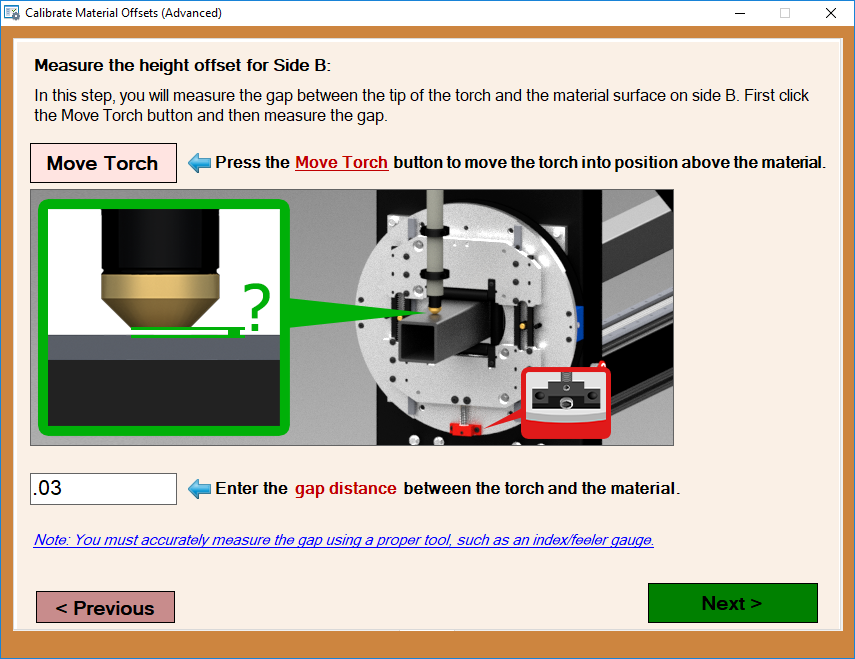

9.

In this step the gate should be rotated to the orientation shown in the picture (90 degrees from home). You will then take a new reading with the feeler gauge on this next face of the tubing (Side B). The reading should be entered into the value field below. Then, click the Next button.

The torch should now raise and the chuck will rotate exactly 90 degrees for use on the next step.

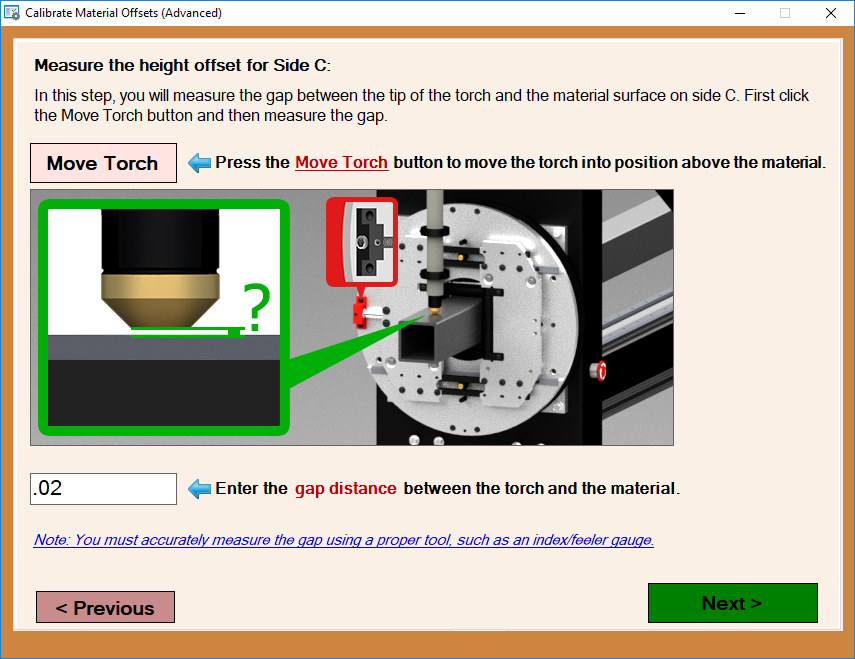

10.

180 degrees from home now you will take another reading from side 3 of the tubing (Side C). The reading should be entered into the value field below. Then, click the Next button.

The torch should now raise and the chuck will rotate exactly 90 degrees for use on the next step.

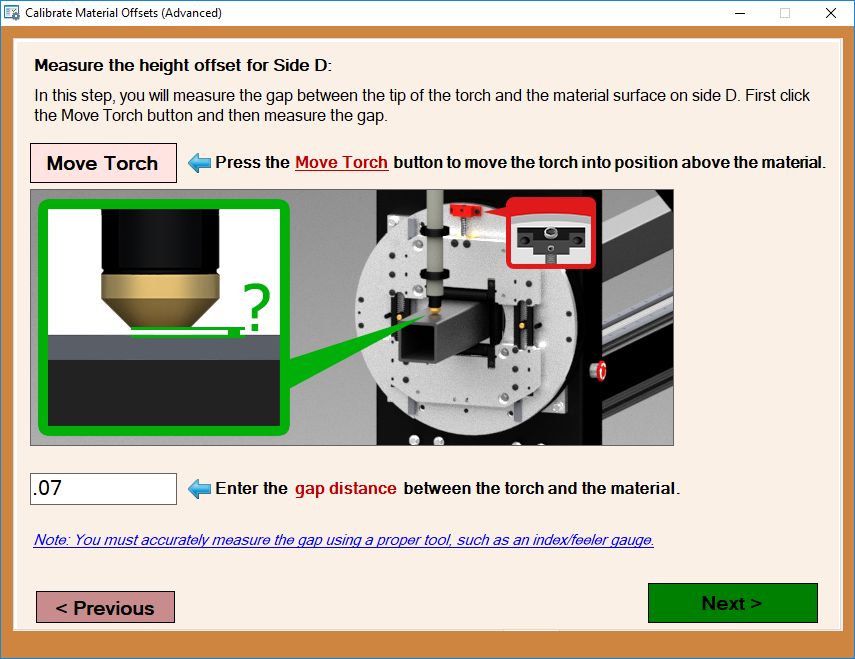

11.

270 degrees from home now you will take a final feeler gauge reading and input the distance once again for (Side D). Then, click the Next button.

The torch should now raise and the chuck will rotate exactly 90 degrees for use on the next step.

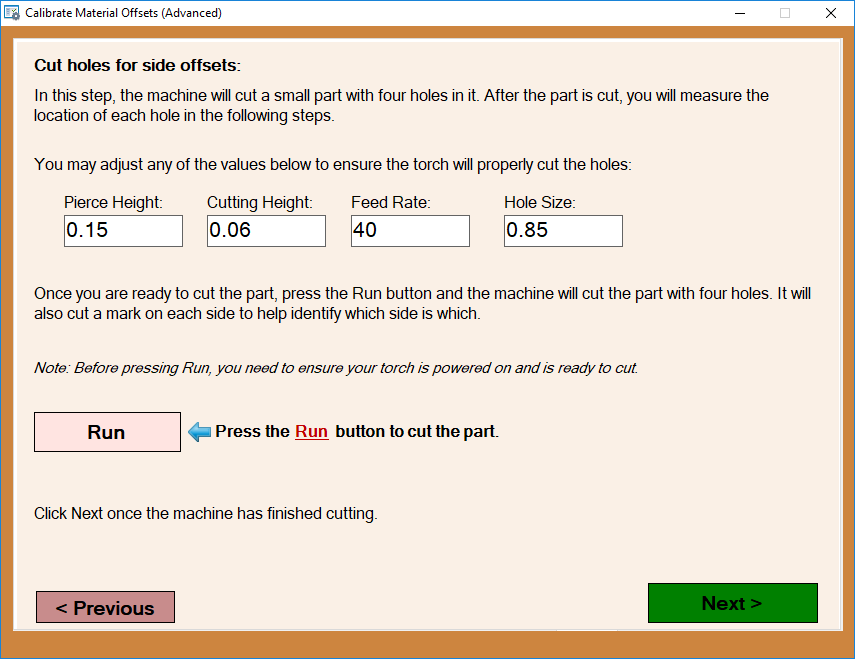

12.

Now, the machine will cut 4 holes, (one on each side of the tubing) while using the new gap readings you've just entered along with the heights, feed rate and hole size you indicate in the value fields on this screen. We suggest a hole size that will not come in close proximity to the corner radius of your material. Click the Run button when you are ready to cut out the holes and click the Next button to proceed to the measuring steps on the next pages.

13

Now, with the gate rotated to its home position once again (Side A) grab a micrometer, or tool gauging to a similar level of precision for use in the next steps.

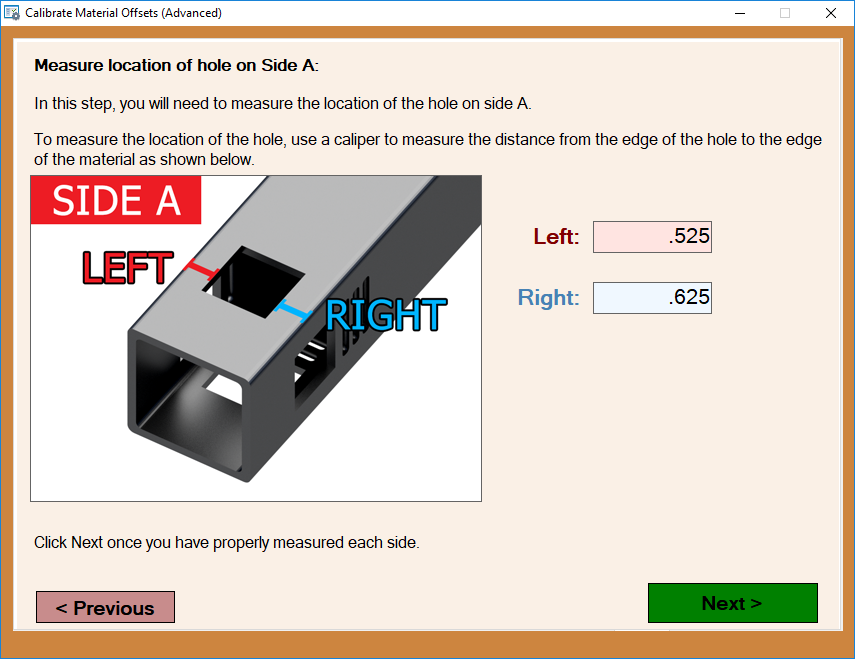

14.

On this screen, take precise measurements from the outside edges of the tube to the outside edges on the hole for Side A. This side will be the side without any additional notches cut into it. The readings should be entered into the value fields below according to the image on the screen.

Then, click the Next button.

15.

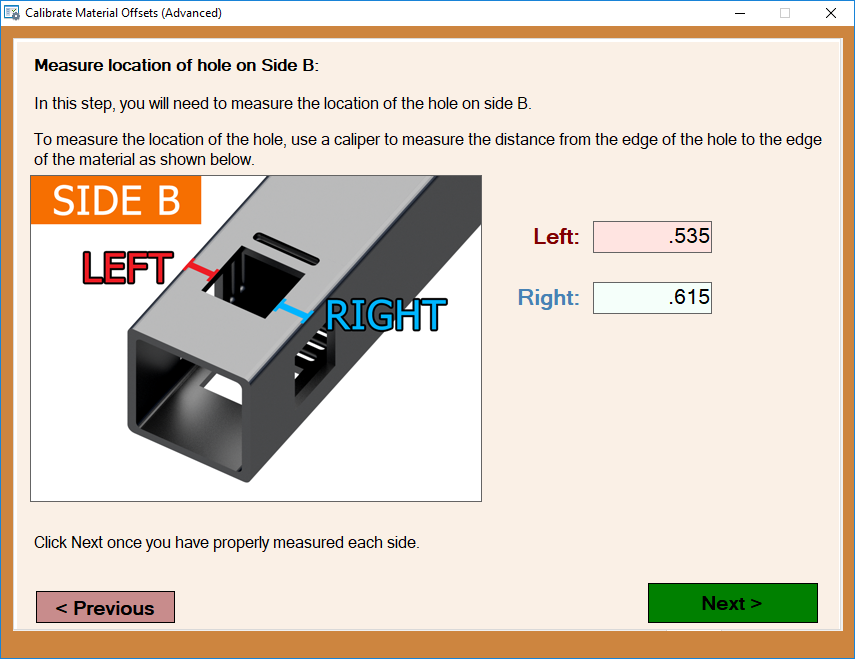

On this screen, take precise measurements from the outside edges of the tube to the outside edges on the hole for Side B. This side will be the side with 1 additional notch cut into it. The readings should be entered into the value fields below according to the image on the screen.

Then, click the Next button.

16.

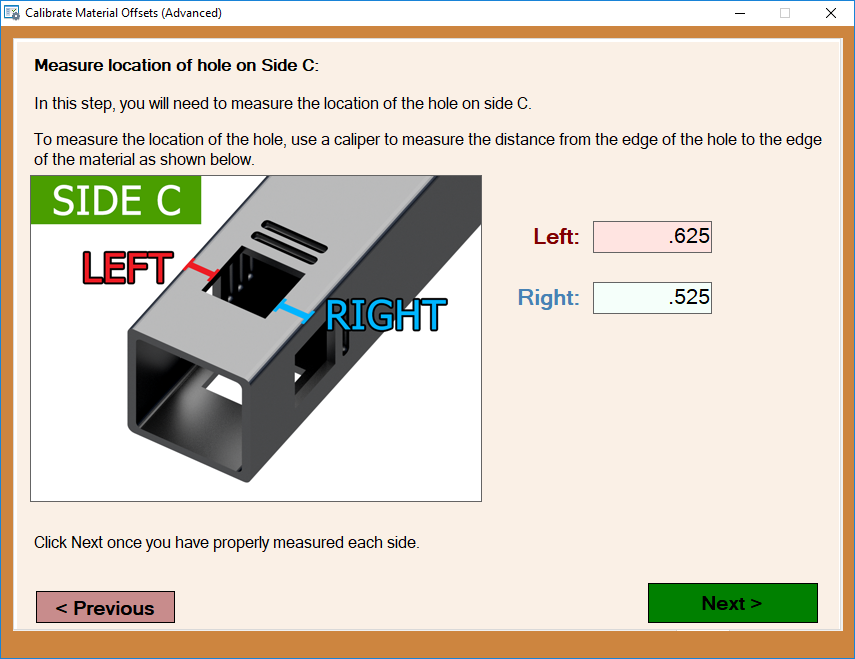

On this screen, take precise measurements from the outside edges of the tube to the outside edges on the hole for Side C. This side will be the side with 2 additional notches cut into it. The readings should be entered into the value fields below according to the image on the screen.

Then, click the Next button.

17.

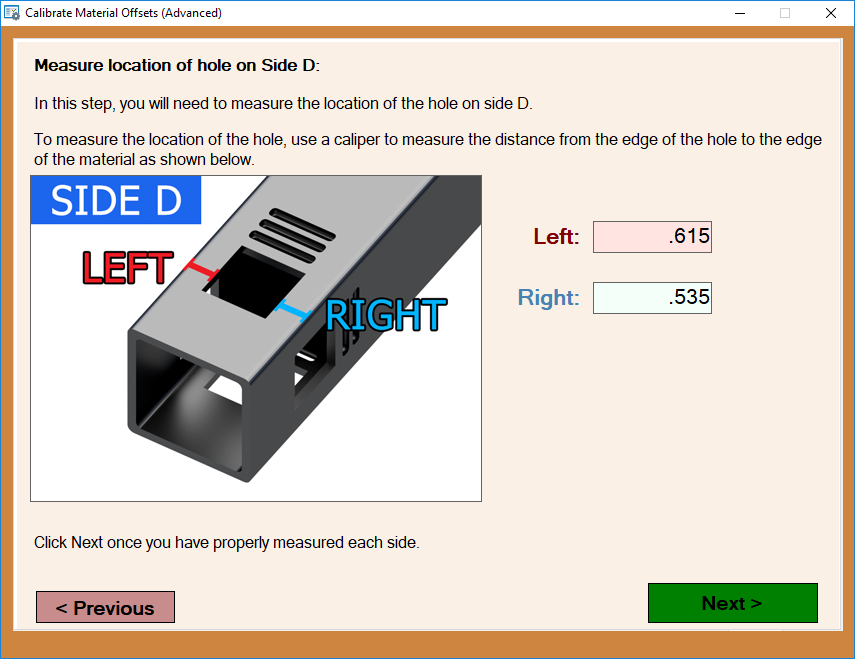

On this screen, take precise measurements from the outside edges of the tube to the outside edges on the hole for Side D. This side will be the side with 3 additional notches cut into it. The readings should be entered into the value fields below according to the image on the screen.

Then, click the Next button.

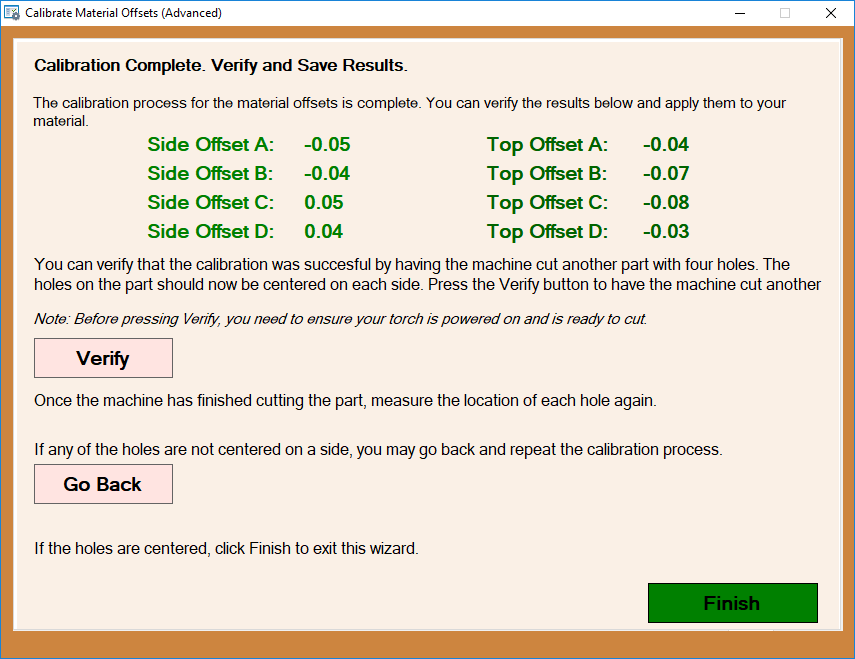

18.

The measurements taken in the entirety of this calibration should appear on this screen. Here, you will have the options to Verify your work, Go Back to redo anything you feel you have done incorrectly, or Finish to complete the calibration.

Your new Side Offsets will be entered into your Advanced tab in the Tube/Pipe Library.

Make sure to save your progress on this screen for use in your jobs including this material.

If you'd like to apply these offsets to another material, you're free to do so as a baseline set of values, but it may not be optimized as much as it is for this particular material.