What is CLR?

CLR is the "Center Line Radius". This is a common term in the tubing industry and it is used to describe the radius of a bend.

The CLR is the radius down the center of the tube. Other fabrication processes use Outside or Inside Radius like Sheet Metal Fabrication. Again, tubing uses the center of the material.

The CLR on many dies will be larger than what is labeled on the die!!! This is especially the case when you are not using a mandrel (most of you are not) and you are not using push assist. This increase in the CLR is caused by "Spring Back". As the material is spinging back the radius is spinging open. Compare this to a copper wire you wrap around a pencil a couple of times. When you release the wire the radius will open up and make the wire fall down the pencil. Same thing is happening with most dies and the tubing.

How do I find the true CLR?

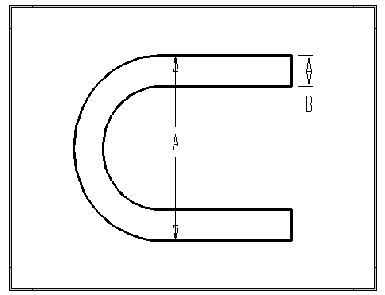

If your die allows you to bend 180 degrees then: Bend a tube to 180 degrees after spring back. Measure the outside of the legs near the start and end of the bend “A”. Measure the tube outside diameter “B”.

Formula: CLR = (A-B) / 2

If you die does not allow for 180 degree bends then:

For most benders use this formula: Formula: CLR = die size * 1.042

On benders using mandrel or push assist use the CLR labeled (or die size) on the die. NOTE: A mandrel bender is the environment where you have a rod inside the tube to hold the wall while bending.

When the value for the CLR is found you need to update the tool in the tooling library.