SolidWorks Import Tutorial II

Things To Know

- This tutorial will step you through the process of exporting a file from SolidWorks and importing it into Bend-Tech. As you walk through this tutorial, procedures are designed based on your knowledge of earlier procedures. Because of this, it is very important that you carefully step through this guide, understanding everything along the way.

A few key items need to be covered before starting the step-by-step instructions of the tutorial. It is very important you completely understand these items:

Centerline & Apex:

Centerline: In the Bend-Tech environment we are working exclusively with the centerline of a part, as compared to the inside or outside.

Apex: The bend locations are defined exclusively with the apex. Our definition of apex is the intersection of the straight tubes as if there wasn’t a radius.

Create Parts: It is possible to create parts in the single part and assembly interfaces of Bend-Tech SW, however, this guide focuses on using part geometry within SolidWorks™ to export into Bend-Tech SW.

Installation: You must have both SolidWorks™ and Bend-Tech SW loaded on the same computer. If installed correctly, you should find a menu selection in SolidWorks™ labeled Bend-Tech. This menu will only be available in SolidWorks™ Part mode and will not be seen in the Assembly mode of SolidWorks™.

Bend-Tech SE vs. SW: Bend-Tech SW contains all the functionality and features of Bend-Tech SE, as well as the ability to import parts directly from SolidWorks™. Any information available for Bend-Tech SE also applies to Bend-Tech SW.

Tutorial

Settings

1. To begin, start up the "Bend-Tech 7x" program.

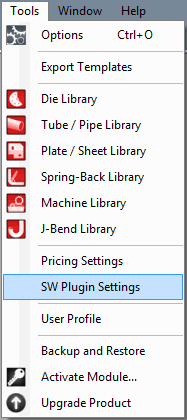

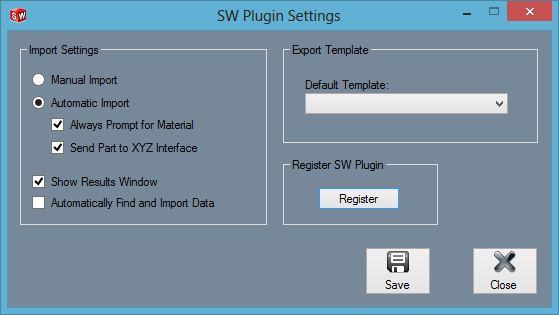

2. Before starting, we must first adjust some settings. Go up to the Tools menu in the main menu bar. Click SW Plugin Settings in the drop down menu.3. In the SW Plugin Settings window, make sure Automatic Import is selected option under the Import Settings section. If not, click the circle next to Automatic Import to set it as the SolidWorks™ import method. Also, put checks in the checkboxes marked "Always Prompt for Material, Send Part to XYZ Interface and Show Results in Window". After these changes are made, click the Save button and then click Close. See picture below for clarification.

- This window also provides the option to set a default template for exporting, to automatically find and import data, and to register the SW Plugin.

Bend-Tech SE vs. SW: Bend-Tech SW contains all the functionality and features of Bend-Tech SE, as well as the ability to import parts directly from SolidWorks™. Any information available for Bend-Tech SE also applies to Bend-Tech SW.

SolidWorks

1. To be able to go through this tutorial, you must have a completed SolidWorks part file available. If not, create a part in SolidWorks™ and come back to this tutorial before continuing on.

2. Once a part is ready, ensure that both SolidWorks™ and Bend-Tech are both open and running.

3. In SolidWorks™, select either the 3D Sketch or Sweep of the part from the Features list on the left side of the frame as shown below. Once selected the sweep or 3D sketch name will be highlighted in blue.

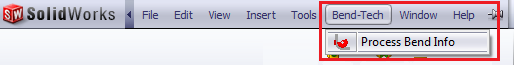

4. Once the sketch or sweep line has been selected, go up to the top left of the SolidWorks window and place your cursor over the right pointing arrow to access the menu bar. In the menu bar, go to the Bend-Tech option and click on Process Bend Info.

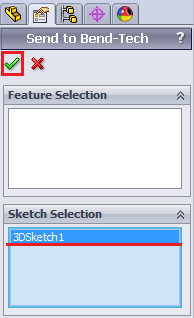

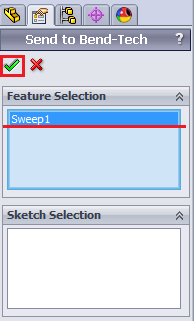

5. Once Process Bend Info has been selected, the Send To Bend-Tech panel will be opened on the left side of the window. Depending on what kind of feature you selected (3D Sketch or Sweep), it will be shown in either the Feature Selection or Sketch Selection box. Make sure that the listed feature is correct, click on it to select it, then click the green check button.

Part Definition

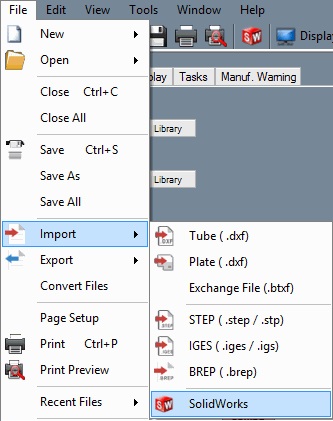

1. Now, back in the Bend-Tech window it's time to import the part information. To do so, either click on the SolidWorks™ icon in the icon toolbar or go to File --> Import --> SolidWorks. This will bring the part information into a Bend-Tech Import Part window.

"(Note) If the material cannot be successfully tracked and imported, a message box (shown below) will appear. In this case, you need to manually import the part in the import window. Click Yes to open the Import interface. See the SolidWorks Tutorial - Part Definition Section for a step by step Import walkthrough. If you do not see this message box, proceed to the next step."

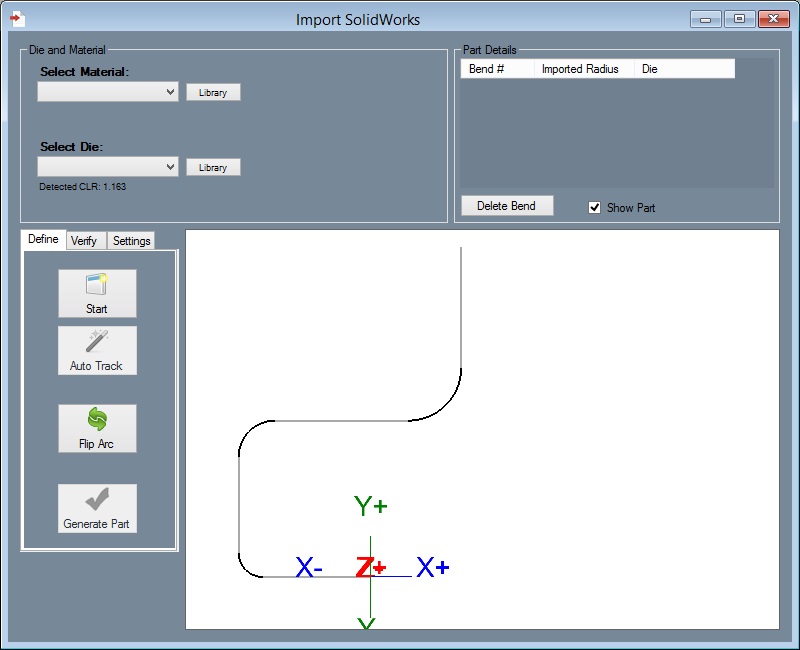

2. A skeleton frame of the part will be shown in the part display window. Each section will have its own PickPoint. Straight sections have a gray outlined point and arcs/circles will have black outlined points.

"Note: From now on, only one part will be shown in the images. Both parts (Exported using 3D Sketch or Sweep) are imported using the same methods."

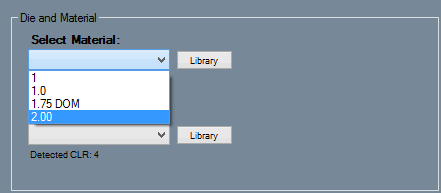

3. Select a material from the "Select Material" drop down menu in the top corner. Since we are not working with the same part, you must choose a material that will work properly with your part design. If necessary, click the library button to open the "Tube/Pipe Library" to add or adjust any materials.

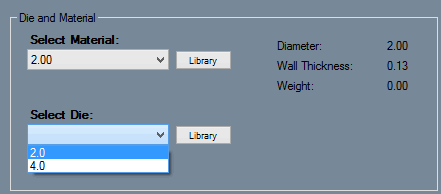

4. Next, select a die from the "Select Die" drop down menu. Notice how the imported CLR is listed directly below this drop down menu. Since this specific part has a 2 inch CLR, a 2.0 CLR die has been selected. Choose a die that is either close to the imported CLR or a die that you will be using when creating this part later on.

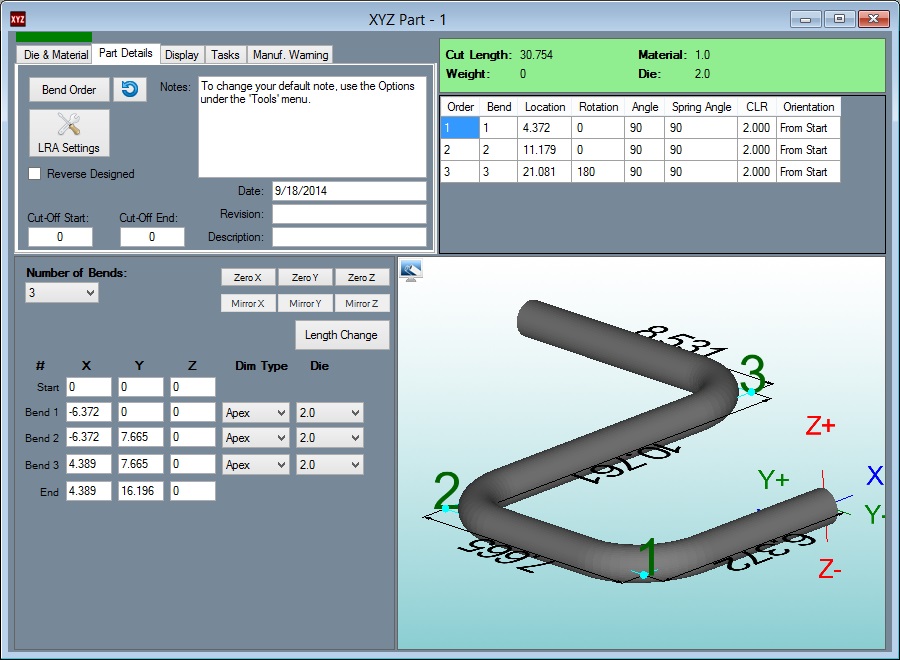

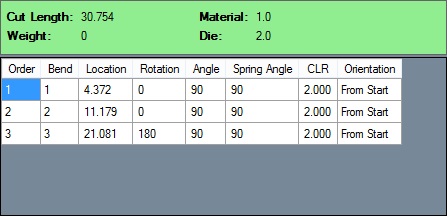

5. Once the part has been successfully imported automatically, the "Part Details" window and an "XYZ Part" design window will be opened. In the XYZ Part design window, the part can be adjusted further, saved, or a setup sheet for the part can be printed. The import process is complete. Now, move on to the Part Details window.

6. In the Part Details window, the top part of the window is occupied by a text box containing information about the part. If necessary, you can type directly in this area to either change or add new information.

7. The information and formatting displayed here is determined by the template that is currently in use. To change templates, select a new template from the drop down menu below "Default Template" in the SW Plugin Settings option.

8. Select the "Part Details" tab at the top of the screen to add some cut-off lengths. Type "5" into both the "Cut-Off Start" and "Cut-Off End" value fields. Notice how the cut length (if included in the template) will adjust to compensate for these values. The lengths in the LRA table (while in either mode) will also be affected by any values entered here.

The tutorial is now complete.