Difference between revisions of "Custom 3D Part"

| Line 67: | Line 67: | ||

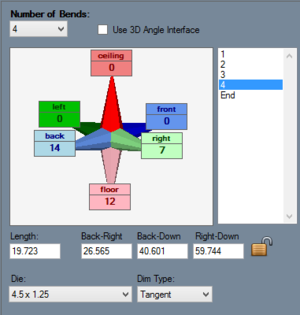

| − | '''Each bend can be assigned a die''' by either selecting the bend number in the bend list and selecting a die or custom CLR from the drop down menu next to 'Die:' or clicking the 'Detailed Die List', clicking on the desired die, and clicking the 'Select' button. Each bend can also be assigned to a dimension type by selecting a bend from the bend list and selecting either Apex or Tangent from the drop down menu next to 'Dim Type:'. Apex will measure to the outside intersection (apex) of the bends two legs. Tangent will measure to the edge of the bends, the tangents, so no bent material will be included in the measurements. | + | |

| + | [[File:custom3d_5.png|right|300px]]'''Each bend can be assigned a die''' by either selecting the bend number in the bend list and selecting a die or custom CLR from the drop down menu next to 'Die:' or clicking the 'Detailed Die List', clicking on the desired die, and clicking the 'Select' button. Each bend can also be assigned to a dimension type by selecting a bend from the bend list and selecting either Apex or Tangent from the drop down menu next to 'Dim Type:'. Apex will measure to the outside intersection (apex) of the bends two legs. Tangent will measure to the edge of the bends, the tangents, so no bent material will be included in the measurements. | ||

Revision as of 15:57, 4 June 2014

Bend-Tech 7x Wiki :: Custom 3D Part

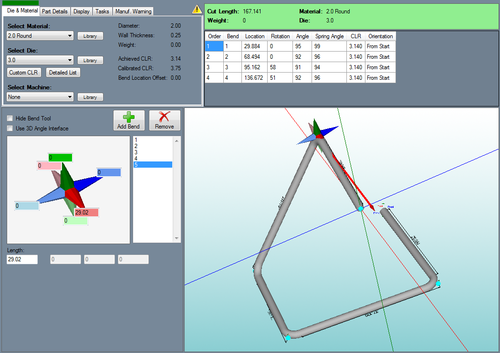

Custom 3-dimensional parts can be created by entering ceiling/floor, left/right, and back/front coordinates or by using the 3D angle interface.

Selection

To create a Custom 3D Part:1.) Go to the File menu, select New, then select Tube. In the Create New menu, click on the Custom 3D Part option.

2.) Click the New Part icon and select the Custom 3D Part option in theCreate New menu.

...OR

3.) Select the Custom 3D Part option from the task menu that appears when the software starts up or when all designs are closed.

Design

Once 'Custom 3D Part' is selected, a new custom 3D part design window will open. If a default die and material have not been set, a die and material must be chosen before designing the part. If necessary, choose a material, die, and/or machine in the Die and Material tab. Once a die and material are selected, the custom 3D part design section will appear.

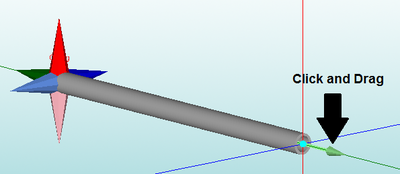

The harpoon has six different direction points. Each will pull the current straight length of the part in the chosen direction.

To start designing the part, click and drag one of the points in the desired direction. The straight length of part will be dragged out from the harpoon. This can also be done by clicking the direction point and directly keying in the distance value or by entering values into the designer entry fields on the left.

Note: A single straight length can be dragged in 3 total directions. For example, if the darker green harpoon point is dragged out, the light green arrow cannot be pulled. In the designer entry fields, if the light blue field has a value of 500, it will be set to 0 if any values are entered in the darker blue field.

In summary, part designs can be edited using 3 different methods:

1.) By selecting a harpoon point and dragging it into place.

2.) By selecting a harpoon point and keying in the value.

3.) By entering values directly into the fields on the left of the screen.

As the part is being drawn, the lengths, angles and rotations will be automatically generated in the designer entry fields on the left of the screen. The values in the colored fields in the harpoon frame show how far and in which direction the current length of tube has been moved.

Individual bends' angles can be locked by clicking on and toggling the lock icon on or off. When a bend is locked, the angles of the bend will be locked in place if any attempts to change them are made. While locked, dragging the harpoon points will only adjust the length of the straight after the bend

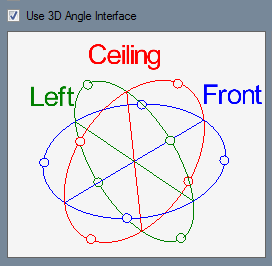

The blue, red, and green circles each represent a plane or dimension- the green section is the right/left plane, the red section runs from the ceiling to the floor, and the blue section is the front/back plane. Each of these planes has four white points separated by 90 degrees around the edge. To enter coordinates while in the 3D Angle Interface, select the bend and select one of the white points on a plane to choose a direction. Once a direction is chosen, enter any necessary values into the Angle and Length, Ceiling, Floor, Back, Front, Left, or Right fields that appear below the compass. Only one of these three fields to the right of the 'Angle' field can have a value at a time. For example, if a value is entered into 'Length' field while the 'Back' field has a value, the 'Back' field will be set to a zero.

To rotate the compass, click and hold the right mouse button and move the cursor to rotate.