Difference between revisions of "Die Library"

(Created page with "'''Bend-Tech 7x Wiki :: Main Menu Bar :: Tools :: Die Library''' right|500px '''View/Edit''': To view and/or edit a die's in...") |

|||

| Line 1: | Line 1: | ||

'''[[Main Page|Bend-Tech 7x Wiki]] :: [[Main Menu Bar]] :: [[Tools]] :: Die Library''' | '''[[Main Page|Bend-Tech 7x Wiki]] :: [[Main Menu Bar]] :: [[Tools]] :: Die Library''' | ||

| + | __NOTOC__ | ||

| + | |||

| + | [[File:die_library_1.png|right|500px]] | ||

| + | |||

| + | The die library stores all the dies available to bend parts. Each die is assigned a set of attributes such as name, achieved CLR, calibrated CLR, minimum distance before a bend, minimum start length, minimum end length, minimum distance between bends with and without rotation, and specific user defined attributes. | ||

| + | |||

| + | |||

| + | Each die can be calibrated using the calibration function and there is a list of predefined dies from a number of different bender models. | ||

| + | |||

| + | |||

| + | In the die library window, there is a list of all dies in the library on the left. The add and delete buttons are located below this list. To the right, the attributes of the currently selected die are shown. The calibration, die list, and save buttons are situated below the attribute fields. | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

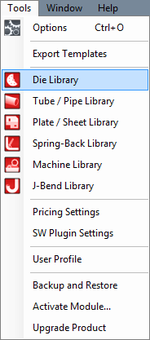

| + | [[File:die_library_2.png|left|150px]] To access the die library, click on the '''Tools''' menu and click on the '''Die Library''' option in the drop down menu. | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| Line 15: | Line 46: | ||

| + | |||

| + | |||

| + | |||

| + | <h3>Add Die</h3> | ||

| + | |||

| + | :<h4>Manual Entry</h4> | ||

| + | |||

| + | To manually add a die to the die library, click the '''Add''' button [[File:add_die.png]] below the die list. After this button is clicked, all the attribute fields will be available to enter data into. Once all the required details are provided, click the '''Save''' button [[File:save_die.png]] to add the die to the library. | ||

| + | |||

| + | |||

| + | :<h3>OEM List</h3> | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | [[File:die_library_4.png|right]] | ||

| + | |||

| + | |||

| + | <h3>Die Details</h3> | ||

| + | |||

| + | *'''Die Name:''' The name given to the die. This will be the what the die is called throughout the software. | ||

| + | |||

| + | |||

| + | *'''Achieved CLR:''' The CLR that the die will actually produce when bending. This value compensates for spring-back and other factors that contribute to inaccuracies in the CLR of a bend. | ||

| + | |||

| + | |||

| + | *'''Calibrated CLR:''' This is a value that is generated and used by the software to ensure accuracy. In general, this value should be 5 to 20% larger than the achieved CLR (''the actual CLR that the die will produce''). '''''To get this value, the [[Calibration|calibration wizard]] or the [[Die Library#OEM Die List|OEM die list]] must be used'''''. | ||

| + | |||

| + | |||

| + | *'''Die Angle:''' This is the angle of the material groove on the die. See image below for an example. | ||

| + | |||

| + | :::[[File:die_library_3.png|300px]] | ||

| + | |||

| + | |||

| + | *'''Bend Location Offset:''' The offset distance between the mark on the tube and the actual starting point of the bend. For example, if the bend offset is 0, the bend starts exactly where the mark is placed. | ||

| + | |||

| + | |||

| + | *'''Units:''' Die specifications can be given in either inches or millimeters. | ||

| + | |||

| + | |||

| + | *'''SpringBack:''' | ||

| + | |||

| + | |||

| + | *'''Worksheet:''' The '''Worksheet''' button [[File:worksheet.png]] can be used to calibrate the current die. See the '''''[[Calibration]]''''' page for more information on how this tool works. | ||

| + | |||

| + | |||

| + | *'''OEM List:''' The OEM list contains a variety of dies and their specifications for different machines. See the [[Die Library#OEM List|OEM list]] section for more specific information. | ||

| − | + | [[File:die_library_5.png|right]] | |

| + | <h3>Die Limitations - Minimum Distances</h3> | ||

| + | If necessary/known, limitations can be added to the selected die. | ||

| − | |||

| − | * | + | *'''Start End:''' This is the shortest amount of tube length allowed at the very beginning of the tube before the first bend. This measurement will start at the starting end of the tube and end at the start of the first bend when the bend is as close to the starting edge as possible. |

| − | |||

| − | ''' | + | *'''Far End:''' This is the shortest amount of tube length allowed at the end of the tube after the last bend. The measurement will begin at the ending edge of the last bend and end at the end of the tube when the bend is as close to the end of the tube as possible. |

| − | ''' | + | *'''Between Bends - with rotation:'''This is the shortest amount of tube length allowed between bends that have rotation. For example, the distance allowed between two bends with a 180° between them. |

| − | |||

| − | * | + | *'''Between Bends - without rotation:''' This is the shortest amount of tube length allowed between bends that have no rotation. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:die_library_6.png|right]] | |

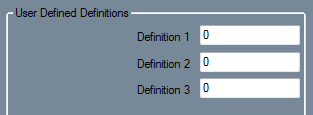

| + | <h3>User Defined Definitions</h3> | ||

| + | Users can also create and define custom die attributes. To create a new definition, click on the '''Setup''' [[File:setup_button.png]] button and enter the names of the definitions into the fields provided. Up to seven different definitions can be created. | ||

| − | + | These definitions and fields will be generated in the User Defined Definitions area for each die in the die library. | |

Revision as of 07:47, 30 May 2014

Bend-Tech 7x Wiki :: Main Menu Bar :: Tools :: Die Library

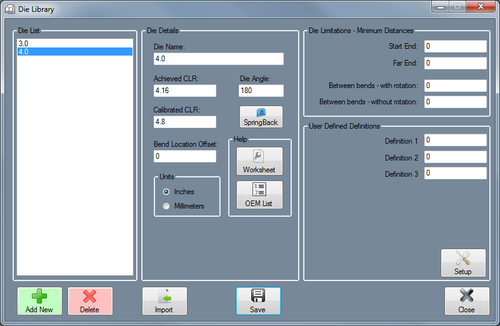

The die library stores all the dies available to bend parts. Each die is assigned a set of attributes such as name, achieved CLR, calibrated CLR, minimum distance before a bend, minimum start length, minimum end length, minimum distance between bends with and without rotation, and specific user defined attributes.

Each die can be calibrated using the calibration function and there is a list of predefined dies from a number of different bender models.

In the die library window, there is a list of all dies in the library on the left. The add and delete buttons are located below this list. To the right, the attributes of the currently selected die are shown. The calibration, die list, and save buttons are situated below the attribute fields.

Add Die

Manual Entry

To manually add a die to the die library, click the Add button ![]() below the die list. After this button is clicked, all the attribute fields will be available to enter data into. Once all the required details are provided, click the Save button

below the die list. After this button is clicked, all the attribute fields will be available to enter data into. Once all the required details are provided, click the Save button ![]() to add the die to the library.

to add the die to the library.

OEM List

Die Details

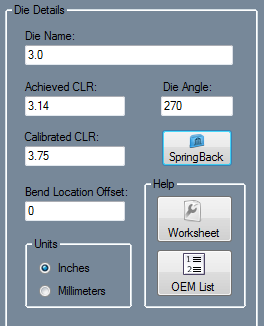

- Die Name: The name given to the die. This will be the what the die is called throughout the software.

- Achieved CLR: The CLR that the die will actually produce when bending. This value compensates for spring-back and other factors that contribute to inaccuracies in the CLR of a bend.

- Calibrated CLR: This is a value that is generated and used by the software to ensure accuracy. In general, this value should be 5 to 20% larger than the achieved CLR (the actual CLR that the die will produce). To get this value, the calibration wizard or the OEM die list must be used.

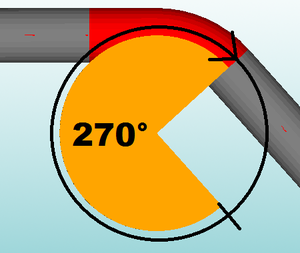

- Die Angle: This is the angle of the material groove on the die. See image below for an example.

- Bend Location Offset: The offset distance between the mark on the tube and the actual starting point of the bend. For example, if the bend offset is 0, the bend starts exactly where the mark is placed.

- Units: Die specifications can be given in either inches or millimeters.

- SpringBack:

- Worksheet: The Worksheet button

can be used to calibrate the current die. See the Calibration page for more information on how this tool works.

can be used to calibrate the current die. See the Calibration page for more information on how this tool works.

- OEM List: The OEM list contains a variety of dies and their specifications for different machines. See the OEM list section for more specific information.

Die Limitations - Minimum Distances

If necessary/known, limitations can be added to the selected die.

- Start End: This is the shortest amount of tube length allowed at the very beginning of the tube before the first bend. This measurement will start at the starting end of the tube and end at the start of the first bend when the bend is as close to the starting edge as possible.

- Far End: This is the shortest amount of tube length allowed at the end of the tube after the last bend. The measurement will begin at the ending edge of the last bend and end at the end of the tube when the bend is as close to the end of the tube as possible.

- Between Bends - with rotation:This is the shortest amount of tube length allowed between bends that have rotation. For example, the distance allowed between two bends with a 180° between them.

- Between Bends - without rotation: This is the shortest amount of tube length allowed between bends that have no rotation.

User Defined Definitions

Users can also create and define custom die attributes. To create a new definition, click on the Setup ![]() button and enter the names of the definitions into the fields provided. Up to seven different definitions can be created.

button and enter the names of the definitions into the fields provided. Up to seven different definitions can be created.

These definitions and fields will be generated in the User Defined Definitions area for each die in the die library.